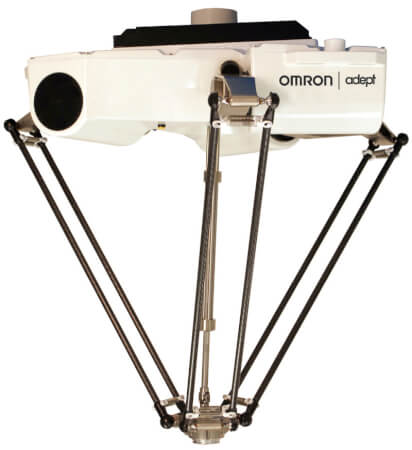

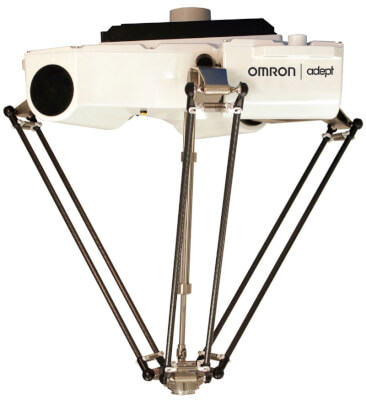

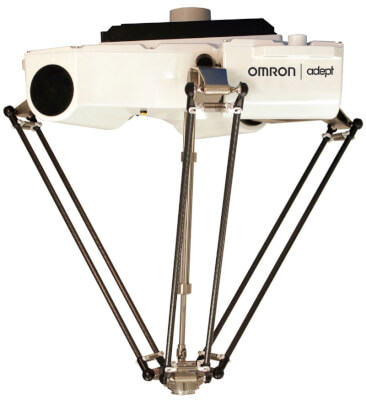

Hornet

Parallel robot ideal for use in the food and beverage, pharmaceutical and healthcare industries

- Ethernet capability to control the robot through the familiar programming language (IEC 61131-3) of NX/NJ machine controller

- The amplifier and controller built into the robot reduces the number of cables

- Tracks up to a conveyor speed of 1.4 m/s

- Designed with a high payload to support multi-hand (multi-picking)

- Helps to reduce mounting cost and robot vibration

- 1,130 mm working range

- Up to 8 kg max. payload

- IP65 protection class

Specifications & ordering info

| Product | Payload | Reach | Robot controller | Z-Stroke | Degree of protection (IP) | Rotation -/+ | Degrees of freedom | Description | |

|---|---|---|---|---|---|---|---|---|---|

|

|

3 kg | 565 mm | Not required | 425 mm | IP20 | 360 ° | 4 | Hornet 565, 3 kg payload, 565mm reach, 360º rotation, 4 axis, 425mm Zaxis, IP20, ePLC |

|

|

|

8 kg | 565 mm | Not required | 425 mm | IP65 | 0 ° | 3 | Hornet 565, 8 kg payload, 565mm reach, 0º rotation, 3 axis, 425mm Zaxis, IP65, ePLC |

|

|

|

3 kg | 565 mm | Not required | 425 mm | IP65 | 360 ° | 4 | Hornet 565, 3 kg payload, 565mm reach, 360º rotation, 4 axis, 425mm Zaxis, IP65, ePLC |

|

|

|

8 kg | 565 mm | EX Controller | 425 mm | IP20 | 0 ° | 3 | Hornet 565, Add-On, 8 kg payload, 565mm reach, 0º rotation, 3 axis, 425mm Zaxis, IP20, ePLC |

|

|

|

3 kg | 565 mm | EX Controller | 425 mm | IP20 | 360 ° | 4 | Hornet 565, Add-On, 3 kg payload, 565mm reach, 360º rotation, 4 axis, 425mm Zaxis, IP20, ePLC |

|

|

|

8 kg | 565 mm | EX Controller | 425 mm | IP65 | 0 ° | 3 | Hornet 565, Add-On, 8 kg payload, 565mm reach, 0º rotation, 3 axis, 425mm Zaxis, IP65, ePLC |

|

|

|

3 kg | 565 mm | EX Controller | 425 mm | IP65 | 360 ° | 4 | Hornet 565, Add-On, 3 kg payload, 565mm reach, 360º rotation, 4 axis, 425mm Zaxis, IP65, ePLC |

|

Accessories

Ordering information

| Apperance | Type | Name/Specifications | Order code |

|---|---|---|---|

|

Robot Integrated Controller | 16 motion axis, up to 8 robots control | NJ501-R300 |

| 32 motion axis, up to 8 robots control | NJ501-R400 | ||

| 64 motion axis, up to 8 robots control | NJ501-R500 | ||

|

Robot Controller | SmartController EX | 19200-000 |

| SmartController EX + Front Panel | 19300-000 | ||

|

Pendant | T20 Pendant with 10 m Cable | 10046-010 |

| T20 Pendant-Jumper Plug | 10048-000 | ||

| T20 Pendant Wall Bracket | 10079-000 | ||

| T20 Adapter Cable, 3 m | 10051-003 | ||

|

Vision Controller | IPC Application Controller | AC1-152000 |

|

Camera | GigE PoE, 1602 x 1202 pixels, 60 fps, Monochrome, CMOS (1/1.8-inch equivalent), camera cables included (10 m) | 24114-250 |

| GigE PoE, 1602 x 1202 pixels, 60 fps, Color, CMOS (1/1.8-inch equivalent), camera cables included (10 m) | 24114-251 | ||

| GigE PoE, 2048 x 2048 pixels, 25 fps, Monochrome, CMOS (1-inch equivalent), camera cables included (10 m) | 24114-300 | ||

| GigE PoE, 2048 x 2048 pixels, 25 fps, Color, CMOS (1-inch equivalent), camera cables included (10 m) | 24114-301 | ||

| Belt Encoder (Conveyor-Tracking) |

Encoder Kit IP65 | 09742-001 | |

| Y-Adapter Cable, 3 m | 09443-000 | ||

| Encoder Extension Cable, 5 m | 09446-050 | ||

| SCEX-BELT,Y-Adapter Cable, 0.5 m | 09550-000 | ||

| XBELTIO Cable, 0.6 m | 13463-000 | ||

| Additional I/O Options | IO Blox (connect to robot), 8 inputs/8 outputs, cables included (0.3 m) | 90356-30200 | |

| IO Block (connect to previous IO Blox), 8 inputs/8 outputs, cables included (0.3 m) | 90356-30100 | ||

| IO Blox-to-robot Cable, 3 m | 04677-030 | ||

| IO Blox-to-IO Blox Cable, 3 m | 04679-030 | ||

| IO Blox-to-IO Blox Cable, 0.3 m | 04679-003 | ||

| XIO Termination Block, 12 inputs/8 outputs, cables included (1.8 m) | 90356-40100 | ||

| XDIO Termination Block, 50 pin, cables included (2 m) | 09747-000 | ||

|

Front Panel | Front Panel with 3 m cable | 90356-10358 |

| Front Panel Cable, 3 m | 10356-10500 | ||

| Power Supply/Cable | AC Power Cable, 5 m | 04118-000 | |

| 24 VDC Power Cable, 5 m | 04120-000 | ||

| 24 VDC, 6.5 A, 150 W (Front Mounting), Power Supply | S8FS-G15024C

2

Refer to the Switch Mode Power Supply Datasheet

(Cat.No.T207) for details. |

||

| 24 VDC, 6.5 A, 150 W (DIN-Rail Mounting), Power Supply | S8FS-G15024CD

2

Refer to the Switch Mode Power Supply Datasheet

(Cat.No.T207) for details. |

||

| 1394 Cable, 4.5 m | 13632-045 | ||

| eAIB XSYSTEM Cable Assembly, 1.8 m | 13323-000 | ||

| DB9 Splitter, 0.3 m | 00411-000 | ||

| eAIB XSYS Cable, 4.5 m | 11585-000 | ||

| Ethernet Cable | XS6W-6LSZH8SS

2

Refer

to the Industrial Ethernet Cables Catalog (Cat.No.G019) for details. |

||

| Industrial Switching Hubs | W4S1-05C

2

Refer

to the Industrial Switching Hubs Catalog (Cat.No.V227) for details. |

||

| Solenoid Valve Kit | eCobra robots (600, 800, 800 Inverted) | 02853-000 | |

| Cable Seal Kit | Hornet 565 IP65/67, Quattro 650HS IP65/67, Quattro 800HS IP65/67 | 08765-000 | |

| Quattro 650HS Standard, Quattro 800HS Standard | 09564-000 | ||

| eCobra 800 IP65/67 | 04813-000 | ||

| eCobra 800 Inverted IP65 | 09073-000 | ||

|

ACE License | Automation Control Environment (for ACE 4.x) | Please download it from following URL: http://www.adept.com/Robots-Tool |

| ACE PackXpert (for ACE 4.x) | 20409-000 | ||

| ACE Sight Vision Software (for ACE 4.x) | 20410-000 | ||

| ACE PackXpert with ACE Sight Vision (for ACE 4.x) This license contains an ACE PackXpert license and an ACE Sight license. |

20433-000 | ||

|

Related Products | Machine Automation Controller NX/NY/NJ Series | NX/NY/NJ

2

Refer to the Sysmac Catalog (Cat.No.P072)

for details. |

| Automation Software Sysmac Studio | SYSMAC-SE2

2

Refer to the Sysmac Catalog (Cat.No.P072)

for details. |

||

| Collection of software functional componentsSysmac LibraryAdept Robot Control Library | SYSMAC-XR009

2

Refer

to the Sysmac Library Catalog (Cat.No.P106) for details. |

||

| Sysmac Studio 3D Simulation option | SYSMAC-SA4 |

||

Contact your Omron representative for lenses, lights, and licenses.

Sysmac Library

The Sysmac Library is a collection of software functional components that can be used in programs

for the NX/NY/NJ Machine Automation Controllers.Please download it from following URL and install to Sysmac Studio Automation Software.http://www.ia.omron.com/sysmac_library/The Adept Robot Control Library allows you to control Delta, Articulated and SCARA robots manufactured

by Omron Adept Technologies Inc. from the NX/NY/NJ Machine Automation Controller by using the same

instructions and programming methods.

How can we help you?

If you have a question or would like to ask for a quote, please contact us or send a request.

Contact me Hornet

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for Hornet

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadDelta Robot Series

Hornet 565

- Rated working range: Ø 1,130 x 275 mm (Max. 425 mm)

- Max. payload: 3 to 8 kg

- Number of axis: 3+1 (rotational axis optional)

- IP65

Control Units

Videos

-

Omron's Adept Hornet 565

The Hornet 565 is a parallel robot (also called delta robot) for high-speed picking and packaging applications. ** Get Financing Options for Robots 👉 The Hornet 565 features a controller-less architecture with Adept’s powerful controls fully embedded into the base of the robot, saving valuable floor space and reducing installation costs and complexity. The Hornet 565 is part of Adept’s complete robotic packaging solution that includes powerful vision guidance, integrated high-speed conveyor tracking, and easy-to-use application software created specifically for the packaging market. Versus competitive robots, the Hornet 565: - Requires up to 50% less floor space - Has up to a 25% larger workspace volume - Is up to 25% faster - Features a hygienic design with corrosion-resistant materials and IP65 rating for easy wash down More Information:

02:13

Omron's Adept Hornet 565

The Hornet 565 is a parallel robot (also called delta robot) for high-speed picking and packaging applications. ** Get Financing Options for Robots 👉 The Hornet 565 features a controller-less architecture with Adept’s powerful controls fully embedded into the base of the robot, saving valuable floor space and reducing installation costs and complexity. The Hornet 565 is part of Adept’s complete robotic packaging solution that includes powerful vision guidance, integrated high-speed conveyor tracking, and easy-to-use application software created specifically for the packaging market. Versus competitive robots, the Hornet 565: - Requires up to 50% less floor space - Has up to a 25% larger workspace volume - Is up to 25% faster - Features a hygienic design with corrosion-resistant materials and IP65 rating for easy wash down More Information:

-

Omron PackXpert: complete packaging solution

A complete single source integrated solution: robot, vision, motion, design & control. Manage your packaging line on your own with an intuitive, graphical interface. PackXpert Solution brings together our complete line of robotic automation products into a single, fully integrated packaging system. From design to implementation to product changeovers, with PackXpert, you’ll save time, lower costs and reduce the complexity of your packaging line.

01:21

_getting_started_guide_en.jpg)

_users_manual_en.jpg)