FLOW Core Fleet Manager

Centralize your AMR control and monitoring with the Fleet Manager. Optimize your workflow with FLOW Core.

The industry’s leading autonomous mobile robot fleet management solution for factory and manufacturing applications. Automatically manages AMR traffic and tasks based on your priority. Deploy flexibly with secure, scalable virtualization options.

-

OMRON FLOW Core 3.0

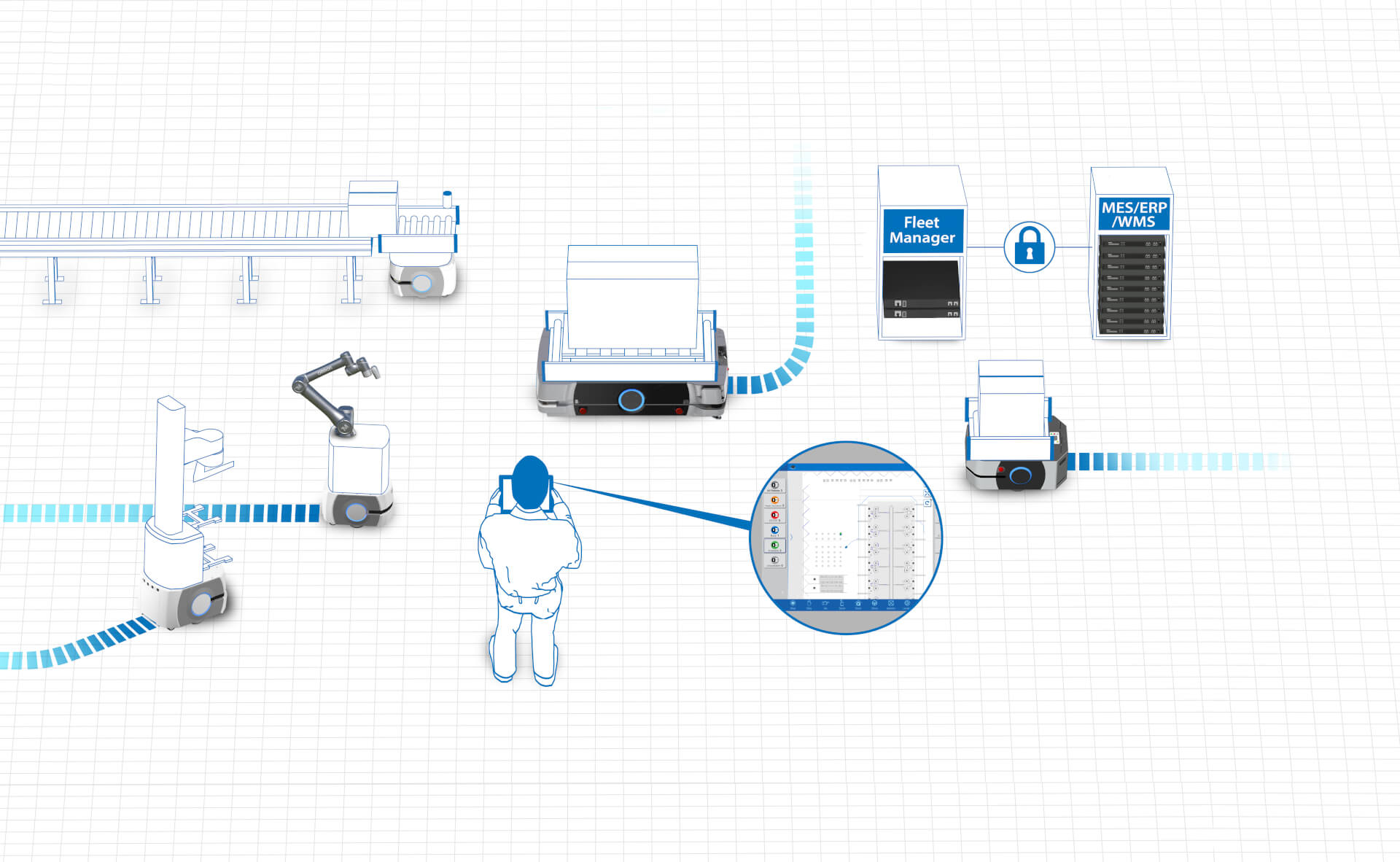

FLOW Core provides the software tools to connect the AMR fleet to the factory’s manufacturing control solution, establish maps, define operational rules, and ensure safe, consistent operation on the factory floor. #omronindustrialautomation

06:40

OMRON FLOW Core 3.0

FLOW Core provides the software tools to connect the AMR fleet to the factory’s manufacturing control solution, establish maps, define operational rules, and ensure safe, consistent operation on the factory floor. #omronindustrialautomationFeatures

Optimize Efficiency

-

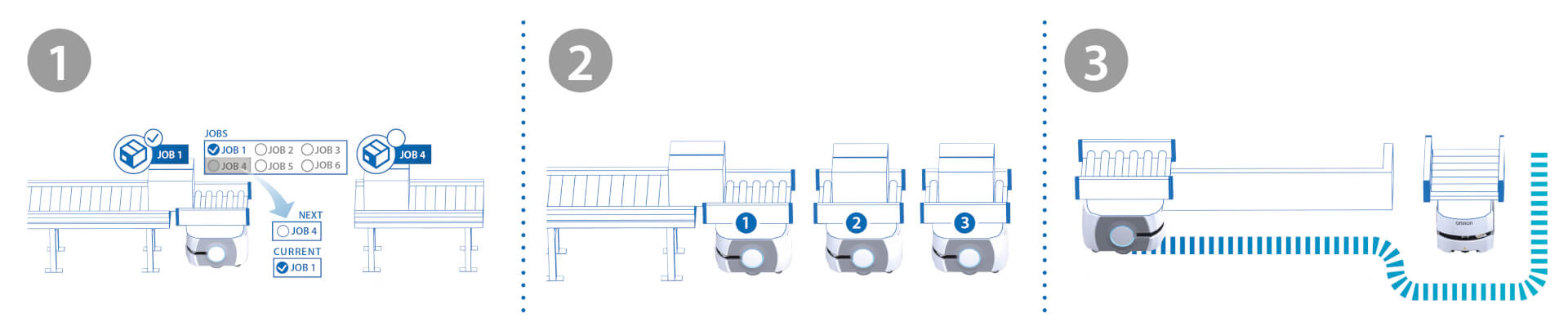

1Intelligent Job AssignmentReduces wasted time and movement by continuously looking ahead to anticipate which robots will be best positioned for upcoming tasks.

-

2Managed MotionEnsures smooth operations in busy environments by coordinating traffic flows and efficiently sequencing pick-up and drop-off at target locations. at target locations.be best positioned for upcoming tasks.

-

3Traffic ControlNotifies converging robots of their predicted paths, allowing them to re-calculate and avoid collision in the most efficient way.

Maximize Uptime

-

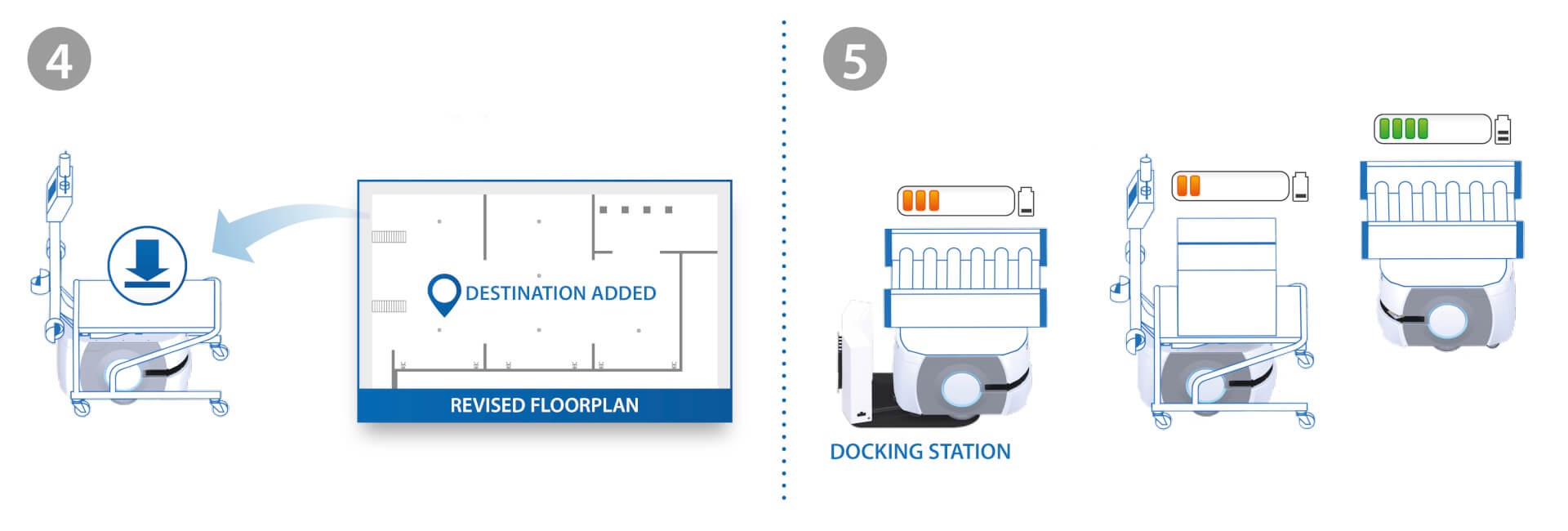

4Automatic UpdatesPerforms updates automatically across the entire fleet.

-

5Change ManagementTracks battery power of the entire fleet, directing robots to their nearest available, or preferred, docking station on a schedule that ensures continuous fleet operation.

Increase Flexibility

-

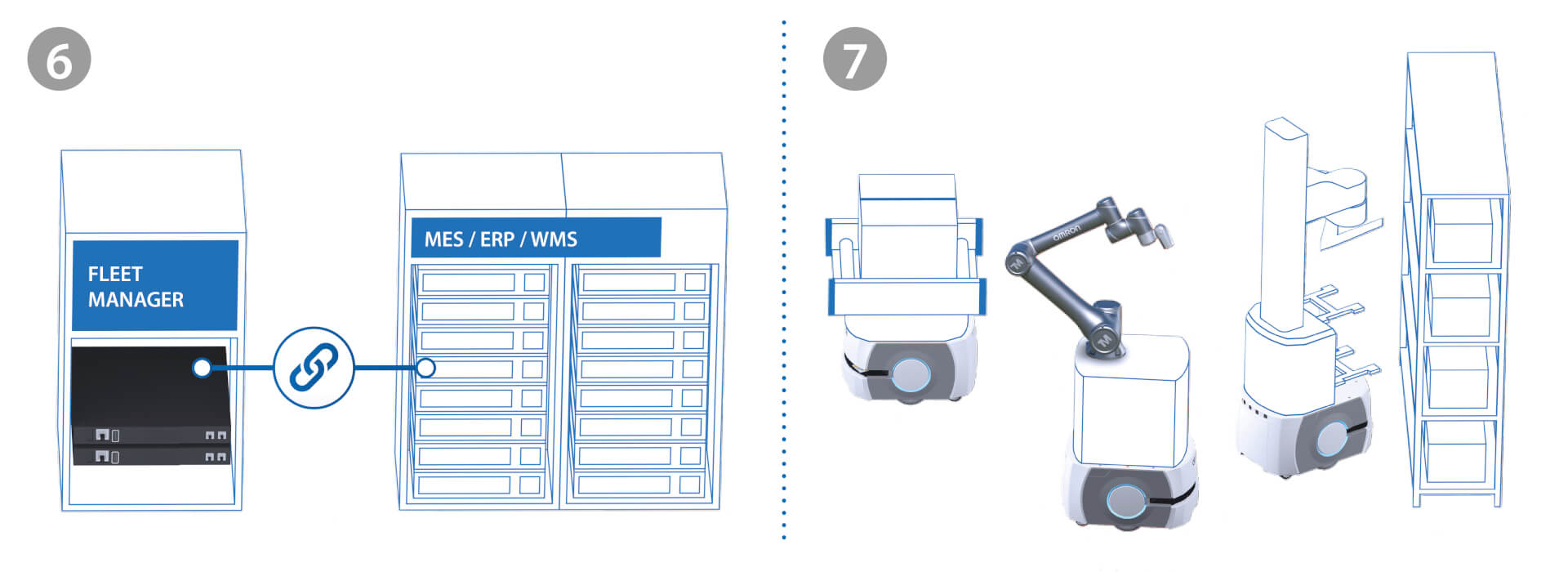

6Easy Integration with IT SystemsFleet Manager can connect to your MES, ERP and WMS so that jobs can be propagated automatically to the fleet in real time.

-

7Skills AdministrationUnderstands the capabilities of each vehicle in the fleet, and always make sure that the right job is assigned to the right robot.

Powerful Fleet Management

Our solution for setting up, integrating and managing autonomous mobile robot (AMR) fleets within a factory environment. FLOW Core provides the software tools to connect the AMR fleet to the factory’s manufacturing control solution, establish maps, define operational rules, and ensure safe, consistent operation on the factory floor. FLOW Software encompasses the following features:

- FLOW iQ

- Integration Toolkit (ITK)

- MobilePlanner 6

- MobilePlanner Tablet Call Button

- Selectable Autonomy

- Dynamic Obstacle Tracking

- Cell Alignment Positioning System (CAPS)

- Fleet Simulator

-

OMRON FLOW Core 3.0

FLOW Core provides the software tools to connect the AMR fleet to the factory’s manufacturing control solution, establish maps, define operational rules, and ensure safe, consistent operation on the factory floor. #omronindustrialautomation

06:40

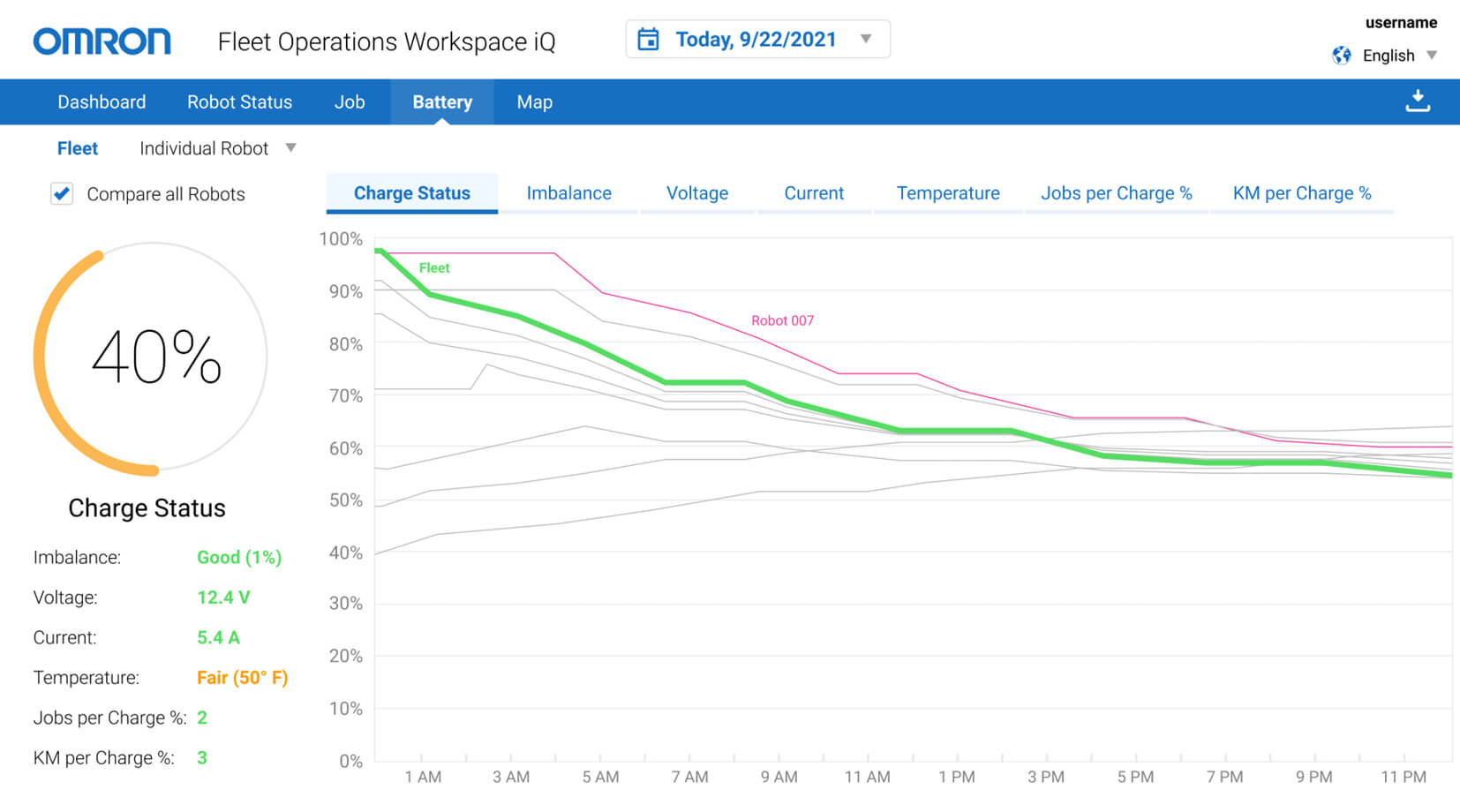

Fleet Operations Workspace iQ

FLOW iQ provides the visualization tools to generate graphics on the fly, and the intelligence to maximize application uptime and lifetime by accelerating failure resolution through giving operators the tools to maintain 24/7 production.

- Quickly view how many robots are working, charging, waiting or reporting an error.

- Visualize the performance of the fleet with flexible job statistics.

- Examine the wireless quality map data to pinpoint network weak spots.

- Track and maintain AMR and battery health with intelligent fault and battery tracking.

- Tailor fleet traffic with localization and position heat maps to maximize cycle time.

-

FLOW Fleet Operations Workspace iQ fleet analytics engine

Fleet Operations Workspace iQ, OMRON’s first fleet analytics engine for application performance and health tracking. Enhancing the core user experience with powerful data collection and analytics through an intuitive user interface. FLOW iQ provides the visualization tools to generate graphics on the fly, and the intelligence to maximize application uptime and lifetime by accelerating failure resolution through giving operators the tools to maintain 24/7 production. Read more:

00:38

Integration Toolkit

The Integration Toolkit is OMRON’s interface application that enables integration between the Fleet Manager and the end user’s client application, manufacturing execution system (MES), or warehouse management system. The Integration Toolkit facilitates queuing and monitoring of all AMR job types such as pickup, drop-off, and multi-segment.

- Standard communication methods including REST, SQL, and AMQP.

- Provide a single contact point for managing a fleet.

- Automate collection of robot and fleet data to use in MES or WMS systems.

- Flexible job assignment allows tasks to be submitted in bulk or dynamically in response to external input.

FLOW Core - Integration Toolkit Brochure

Fleet Simulator

Fleet Simulator Leaflet

-

OMRON FLOW Core 3.0 Fleet Simulator

Our Fleet Simulator offers the industry’s first mobile robot simulator for factory and manufacturing applications. #omronindustrialautomation

00:31

Technology

AMR Technology and Software

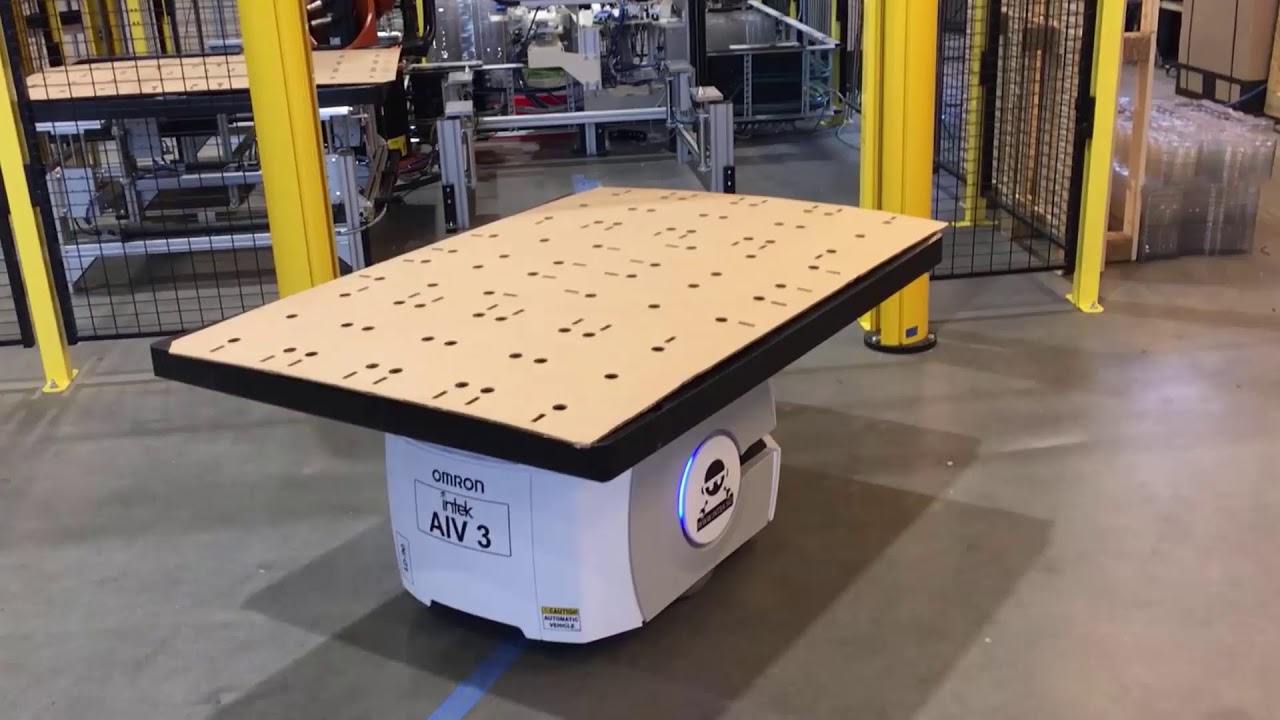

OMRON's Autonomous Mobile Robots (AMRs) are equipped with dedicated AMR technology for navigation and alignment positioning. This technology allows the AMRs to move safely and efficiently within their designated workspaces, even in complex environments. The AMRs are also operated by software, which makes them easy to use and program.

- The dedicated AMR technology used by OMRON's AMRs includes a variety of sensors, such as laser scanners, which allow the robots to accurately map their environment and navigate safely.

- The software used to operate OMRON's AMRs is user-friendly and intuitive, making it easy to program the robots to perform specific tasks.

OMRON Fleet Simulator offers the industry’s first mobile robot simulator for factory and manufacturing applications

Specifications & ordering info

| Product | Max. number of vehicle connections | License period | License version | Description | |

|---|---|---|---|---|---|

|

|

5 | 3 years | Flow Core license | Virtual Fleet Manager - Up to 5 x AMR FLOW Core License, allows 3 Year FLOW Core upgrades |

|

|

|

10 | 3 years | Flow Core license | Virtual Fleet Manager - Up to 10 x AMR FLOW Core License, allows 3 Year FLOW Core upgrades |

|

|

|

15 | 3 years | Flow Core license | Virtual Fleet Manager - Up to 15 x AMR FLOW Core License, allows 3 Year FLOW Core upgrades |

|

|

|

20 | 3 years | Flow Core license | Virtual Fleet Manager - Up to 20 x AMR FLOW Core License, allows 3 Year FLOW Core upgrades |

|

|

|

25 | 3 years | Flow Core license | Virtual Fleet Manager - Up to 25 x AMR FLOW Core License, allows 3 Year FLOW Core upgrades |

|

|

|

30 | 3 years | Flow Core license | Virtual Fleet Manager - Up to 30 x AMR FLOW Core License, allows 3 Year FLOW Core upgrades |

|

|

|

100 | 3 years | Flow Core license | Virtual Fleet Manager - More than 30 AMR FLOW Core License, allows 3 Year FLOW Core upgrades |

|

We've got a nearly-infinite combination to fit any production scenes.

Interested?

Contact me FLOW Core Fleet Manager

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for FLOW Core Fleet Manager

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadApplications & Key Industries

-

Intralogistics process and related challenges

OMRON solution for the complete intralogistics process The complete intralogistics process in a factory is divided into four different groups because the challenges are different, but also the solutions: Lineside Replenishment; Work in progress; Finished goods and Warehouse. Read more on:

03:18

OMRON solution for the complete intralogistics process

Key industries for an Autonomous Mobile Robot

AMRs in automotive manufacturing

In the automotive industry, autonomous mobile robots are often used in transporting work in progress parts or components, as well as connecting different areas of the factory floor with the warehouse, ensuring traceability and quality.

read more

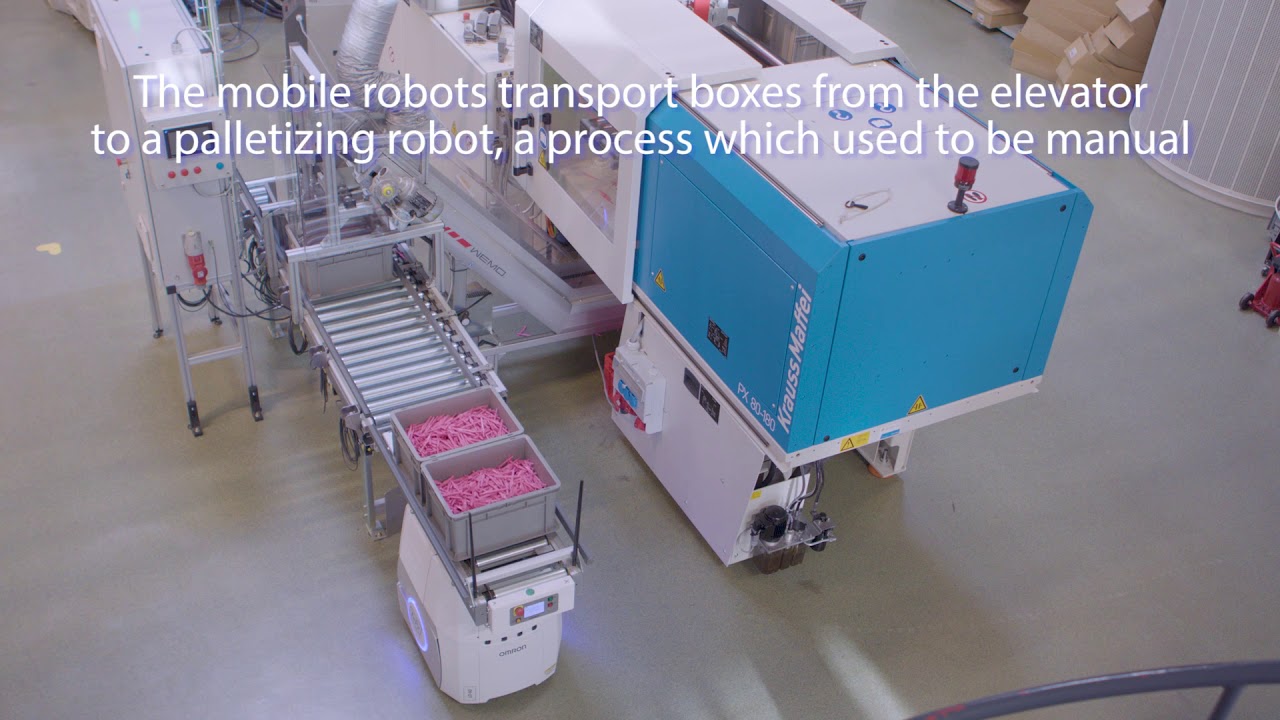

AMRs in food & beverage manufacturing

In food & beverage manufacturing, autonomous mobile robots are key in connecting production lines with for example a palletizing station and the warehouse. They can supply raw material and cartons, remove waste, replace long conveyors and and free up the operators for more value-added tasks.

read more

AMRs in the Life Science industry

In pharmaceutical manufacturing, ARMs, often combined with cobot arms, collect samples, and connect cleanrooms for example with packaging areas, ensuring safety, flexibility and scalability of processes.

read more

AMRs in the Digital & Semiconductor industry

We help the Digital and Semiconductor industry achieve efficient, data-driven and uninterrupted production with our smart manufacturing solutions.

read more

AMRs in other industries

Our automation solutions with mobile robots cover many manufacturing areas. Besides the ones we highlighted, we also serve sectors like Infrastructure, Power and Energy, and more non-industrial applications.

read more

Solutions

Fleet Simulator - Optimize your fleet before you deploy it

Customer Cases

-

Operators and robots work in harmony: Grupo Antolin automates handling of car interior components

Major trends in the automotive industry – including an increasing emphasis on issues such as electrification, digitalization, and sustainability – are also driving changes in vehicle interiors. One of the largest international players in this sector is Grupo Antolin. As a key player at global automotive supply chain and high value manufacturing leader, the strategy of the company, Adv. Manufacturing 4.0, looks into integration of digital technology in the operations. One of the focus areas is the reduction and optimization of movements in internal logistic. Introducing autonomous mobile robots (AMRs) and collaborative robots (cobots), manufactured and supplied by OMRON, helps achieve a modernized and more sustainable factory where people and machines are working in harmony. For more information, visit:

03:11

Operators and robots work in harmony: Grupo Antolin automates handling of car interior components

Major trends in the automotive industry – including an increasing emphasis on issues such as electrification, digitalization, and sustainability – are also driving changes in vehicle interiors. One of the largest international players in this sector is Grupo Antolin. As a key player at global automotive supply chain and high value manufacturing leader, the strategy of the company, Adv. Manufacturing 4.0, looks into integration of digital technology in the operations. One of the focus areas is the reduction and optimization of movements in internal logistic. Introducing autonomous mobile robots (AMRs) and collaborative robots (cobots), manufactured and supplied by OMRON, helps achieve a modernized and more sustainable factory where people and machines are working in harmony. For more information, visit:

-

Material handling solutions with autonomous mobile robots

LCS has implemented applications with OMRON autonomous mobile robots in various markets and industries that require efficient, flexible and automated logistics. LCS Group has been operating on the Italian and European markets since 1989 as a System Integrator, offering complete, integrated and cutting-edge hardware and software solutions for internal logistics, airports and industrial automation. Music in this video Inspirational Corporate Ambient Artist: Aleksandr Shamaluev Album: Corporate Music Licensed to YouTube by HAAWK for a 3rd Party (on behalf of AShamaluevMusic); HAAWK Publishing, BMI - Broadcast Music Inc., and 3 music rights societies

02:36

Material handling solutions with autonomous mobile robots

LCS has implemented applications with OMRON autonomous mobile robots in various markets and industries that require efficient, flexible and automated logistics. LCS Group has been operating on the Italian and European markets since 1989 as a System Integrator, offering complete, integrated and cutting-edge hardware and software solutions for internal logistics, airports and industrial automation. Music in this video Inspirational Corporate Ambient Artist: Aleksandr Shamaluev Album: Corporate Music Licensed to YouTube by HAAWK for a 3rd Party (on behalf of AShamaluevMusic); HAAWK Publishing, BMI - Broadcast Music Inc., and 3 music rights societies

-

Made-to-order production with an advanced fleet of mobile robots at VOLA

VOLA, a Danish manufacturer of luxury sanitary and kitchen fittings, has opened a new factory that incorporates a fleet of nine LD mobile robots from Omron. The new robot fleet works side-by-side with people, and is controlled by an advanced fleet management system. These have replaced roller conveyors, leading to a more flexible production and logistics set-up that matches the company’s single-piece production process, in which everything is produced to order.

02:36

Made-to-order production with an advanced fleet of mobile robots at VOLA

VOLA, a Danish manufacturer of luxury sanitary and kitchen fittings, has opened a new factory that incorporates a fleet of nine LD mobile robots from Omron. The new robot fleet works side-by-side with people, and is controlled by an advanced fleet management system. These have replaced roller conveyors, leading to a more flexible production and logistics set-up that matches the company’s single-piece production process, in which everything is produced to order.

-

Normagrup automates material transport with autonomous mobile robots

Founded in 1971, Normagrup is a world leader in technology dedicated to the production of interior lighting. Following the company’s original spirit and desire to create high-quality, technological products, they also apply this spirit in continuously improving their production processes. When Normagrup decided to automate material transport between production areas, they opted for a fleet of autonomous mobile robots with automatic loading and unloading stations. The project was carried out with Inser Robótica S.A. #mobilerobots #robotics #AMRs #intralogistics

02:21

Normagrup automates material transport with autonomous mobile robots

Founded in 1971, Normagrup is a world leader in technology dedicated to the production of interior lighting. Following the company’s original spirit and desire to create high-quality, technological products, they also apply this spirit in continuously improving their production processes. When Normagrup decided to automate material transport between production areas, they opted for a fleet of autonomous mobile robots with automatic loading and unloading stations. The project was carried out with Inser Robótica S.A. #mobilerobots #robotics #AMRs #intralogisticsVideos

-

OMRON FLOW Core 3.0

FLOW Core provides the software tools to connect the AMR fleet to the factory’s manufacturing control solution, establish maps, define operational rules, and ensure safe, consistent operation on the factory floor. #omronindustrialautomation

06:40

OMRON FLOW Core 3.0

FLOW Core provides the software tools to connect the AMR fleet to the factory’s manufacturing control solution, establish maps, define operational rules, and ensure safe, consistent operation on the factory floor. #omronindustrialautomation

-

OMRON Mobile I/O Box Tutorial Video

The OMRON Mobile I/O Box is an I/O device that can be used to summon an autonomous mobile robot (AMR) to a designated location by just pressing a button. #mobilerobots #omronindustrialautomation

08:56

OMRON Mobile I/O Box Tutorial Video

The OMRON Mobile I/O Box is an I/O device that can be used to summon an autonomous mobile robot (AMR) to a designated location by just pressing a button. #mobilerobots #omronindustrialautomation

-

FLOW Fleet Operations Workspace iQ fleet analytics engine

Fleet Operations Workspace iQ, OMRON’s first fleet analytics engine for application performance and health tracking. Enhancing the core user experience with powerful data collection and analytics through an intuitive user interface. FLOW iQ provides the visualization tools to generate graphics on the fly, and the intelligence to maximize application uptime and lifetime by accelerating failure resolution through giving operators the tools to maintain 24/7 production. Read more:

00:38

FLOW Fleet Operations Workspace iQ fleet analytics engine

Fleet Operations Workspace iQ, OMRON’s first fleet analytics engine for application performance and health tracking. Enhancing the core user experience with powerful data collection and analytics through an intuitive user interface. FLOW iQ provides the visualization tools to generate graphics on the fly, and the intelligence to maximize application uptime and lifetime by accelerating failure resolution through giving operators the tools to maintain 24/7 production. Read more:

-

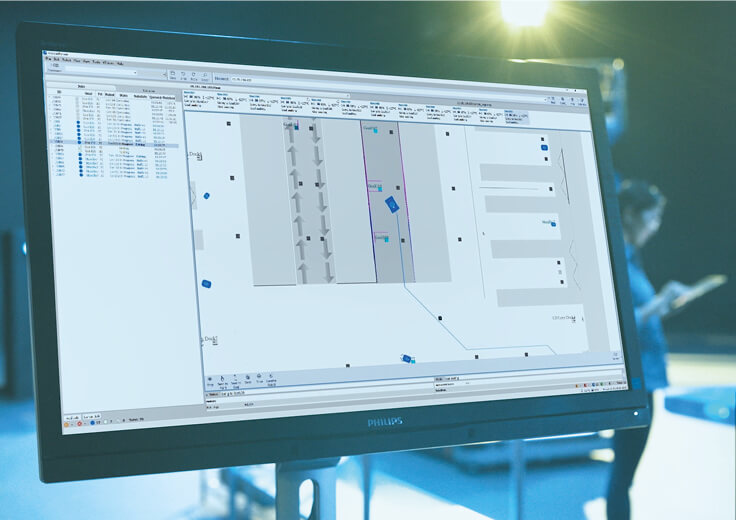

OMRON FLOW Core 3.0 MobilePlanner

Our MobilePlanner allows you to easily and effectively utilize fleets of heterogeneous robot types alongside one another to optimize their automation solution. MobilePlanner expands our Fleet Management ecosystem as the best in the industry. #omronindustrialautomation #mobilerobots

00:53

OMRON FLOW Core 3.0 MobilePlanner

Our MobilePlanner allows you to easily and effectively utilize fleets of heterogeneous robot types alongside one another to optimize their automation solution. MobilePlanner expands our Fleet Management ecosystem as the best in the industry. #omronindustrialautomation #mobilerobotsDownloads

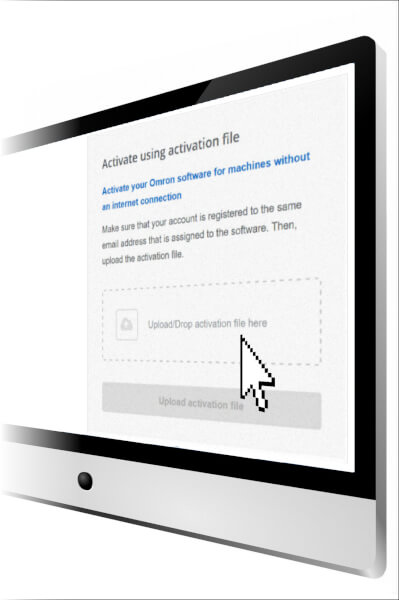

Activate your Mobile Robot Software

How can we help you?

If you have a question or would like to ask for a quote, please contact us or send a request.

Contact me FLOW Core Fleet Manager

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for FLOW Core Fleet Manager

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

Download

_reference_manual_en.jpg)

_datasheet_en.jpg)