Semiconductor industry supply chain optimization

Global demand for semiconductors is higher than ever. It takes a long time to make one – up to six months, excluding packaging and delivery to the customer. Semiconductor companies need to find ways to produce things faster and more efficiently.

Optimizing semiconductor manufacturing is crucial to meet the ever-increasing global demand. Automation and process improvement can significantly enhance wafer yields, reduce material waste, and minimize the financial risks associated with lengthy production cycles. Human involvement in wafer transportation increases the likelihood of errors.

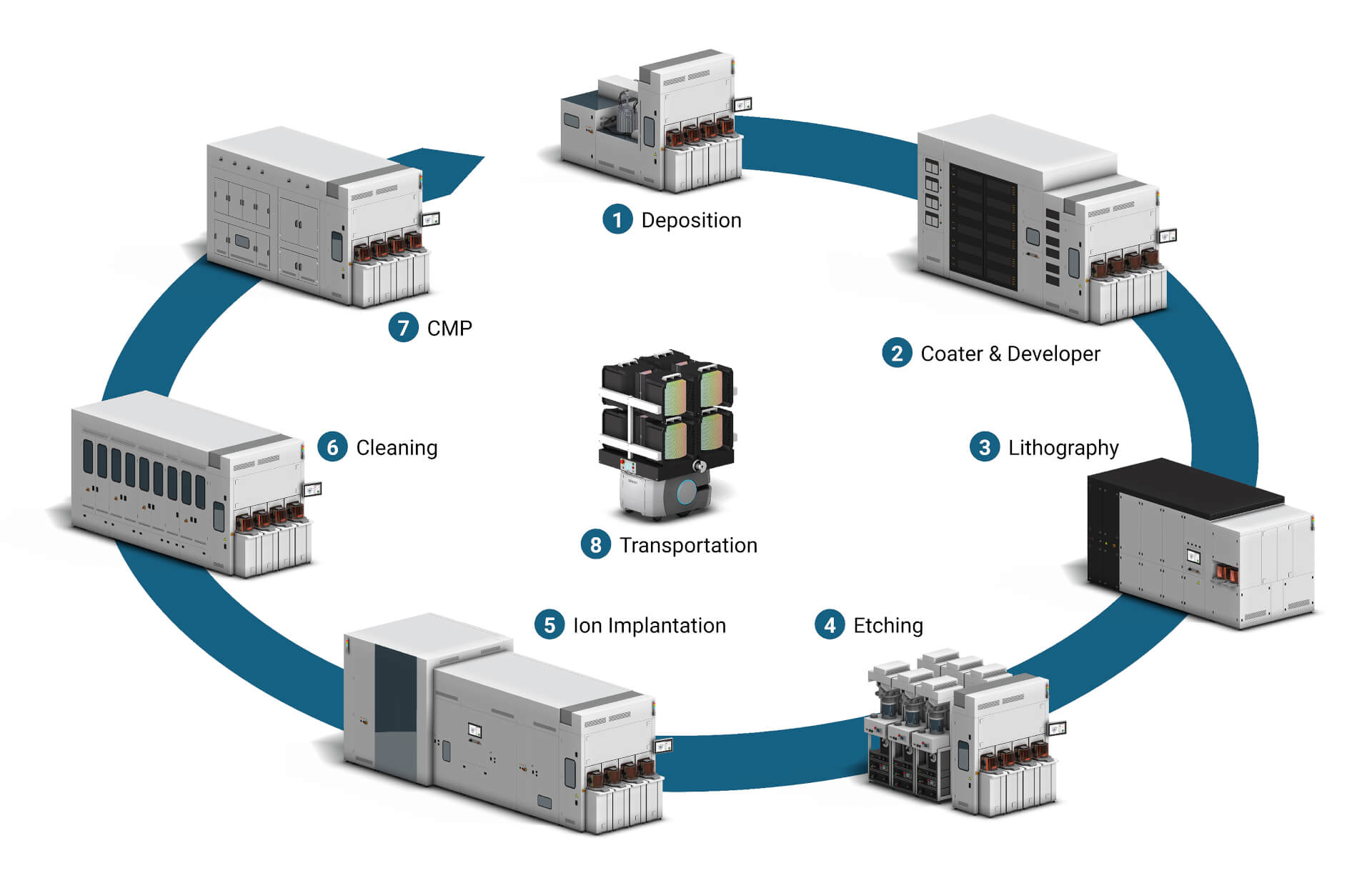

Explore our proven front end chip fabrication solutions

Ready to elevate your chip-making game? Innovative front-end chip fabrication solutions offer precise wafer temperature control, waste reduction, automated transportation, and full FOUP traceability. With our solutions, you’ll have full control of the process, resulting in higher-quality chips produced faster and more efficiently.

Streamline Front-End Fab Operations

Applications

Wafer FOUP Traceability

Tracking FOUPs in the manufacturing process.

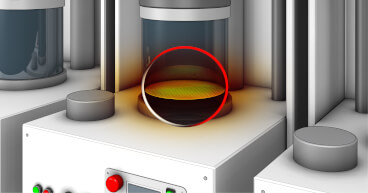

Temperature Control for Wafers

Adapting to changes in the production site environment and environmentally friendly materials / Automatically suppresses temperature variations caused by routine disturbances.

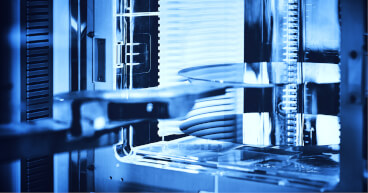

Wafer Transportation

Front-end fabs can benefit greatly from transportation systems that reduce physical labor, lower costs, and minimize inefficiencies. The addition of multiple robots can further enhance efficiency and flexibility.

Safety Network

Safety integration into machine control through open network technology.

Wafer Mapping

Mapping wafers during wafer transfer in semiconductor manufacturing.

Continuous monitoring of electric energy

Monitoring of power consumption of equipment and facilities for energy management.

Do you want to know more?

Contact Our Experts

Contact me Front End Semiconductor Manufacturing

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

Download