Kusatsu Factory, Japan

Integrating advanced technologies and human on-site capabilities for improving productivity and Dbl.ppb-level board mounting quality

OMRON Kusatsu Factory is the site of ultra-high-mix low-volume production: it produces 4,800 different types of controller product items, 85% of which have a monthly production volume of 20 units or less. To streamline such extraordinary production, it is critical that we make effective use of manpower that can be flexibly applied. At the Kusatsu Factory, we strive to improve productivity and innovate quality by continuously accumulating and analyzing production line data, and by exploring ways to effectively integrate advanced production technologies with human on-site capabilities.

Semi-automation through IE task analysis more than doubles mixed flow cell line productivity

Visualizing the entire production line through big data analysis to enable non-skilled workers to extract improvement points in 1/6 the time

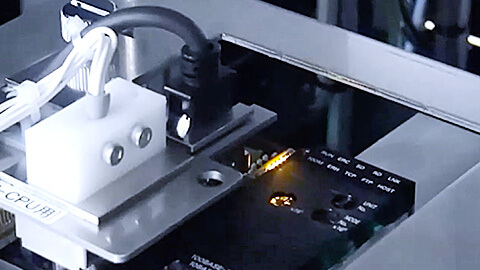

Visualizing changes in individual PCBs through IOT-powered mounting process innovation

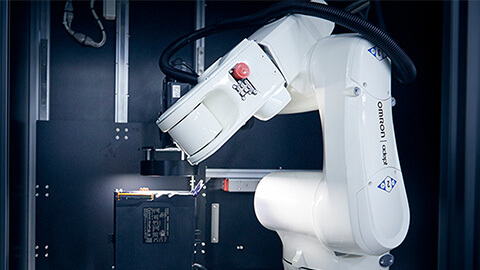

Expanding the application range of automation to further boost ultra-high-mix low-volume productivity

Automating sensory inspections traditionally reliant on the sensory acuity of veteran workers

Kusatsu Factory

Kusatsu City

Shiga 525-0035

Our Worldwide Production Facilities

Strategically implementing i-Automation! to create the factory of the future

read more