Adapting to changes in the production site environment and environmentally friendly materials

As the demand for productivity and quality in semiconductor manufacturing grows, precise temperature control on the wafer surface becomes crucial for equipment performance. Our advanced temperature control technology, developed over many years, ensures uniform temperature regulation at multiple points on the wafer surface.

Application: Wafer surface temperature control

The environment is different at equipment shipping destination and PID adjustments must be made again on-site. PID adjustment is required for each workpiece type, and it makes changeover time-consuming.

Our solution: Modular advanced temperature control

Our NX-TC temperature control unit frees production sites from onerous commissioning and adjustment work. It captures changes in conditions that can impact quality, like a skilled worker would, and automatically makes PID adjustments to deliver temperature control that constantly maintains optimal conditions.

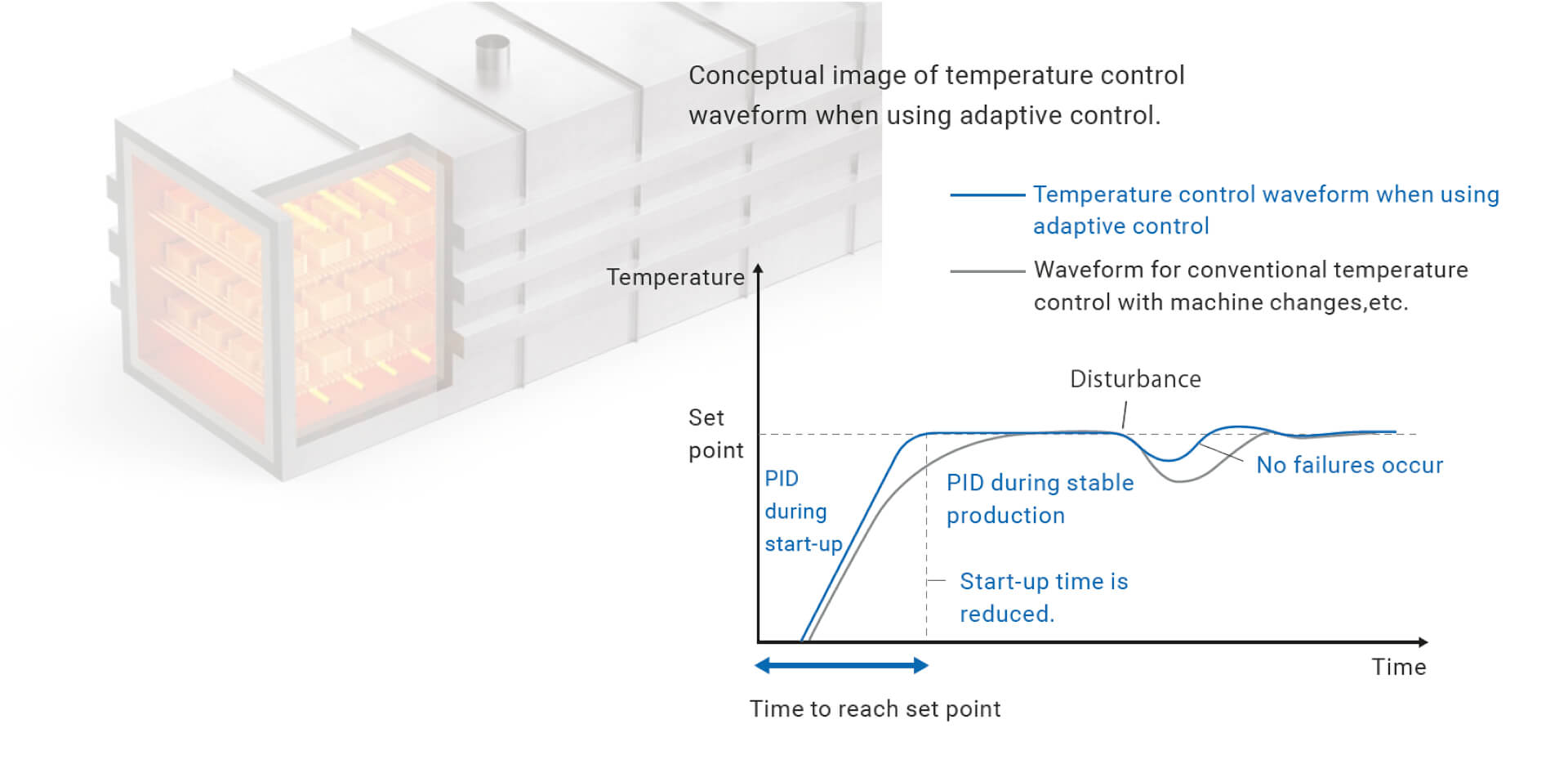

With the 'adaptive control' technology incorporated into this product, the optimal PID values are calculated automatically for both the time of the start-up and for during stable production. Furthermore, it is possible to monitor the temperature control status of the machine to automatically adjust the PID value to obtain the optimal temperature control in response to changes such as workpiece changes and machine changes.

Automatically suppresses temperature variations caused by routine disturbances

Provides stable automatic control against foreseeable temperature variations. Contributes to quality improvement and helps boost production capacity by reducing the wait time until temperature stabilization.

Application: Precise temperature control with disturbances

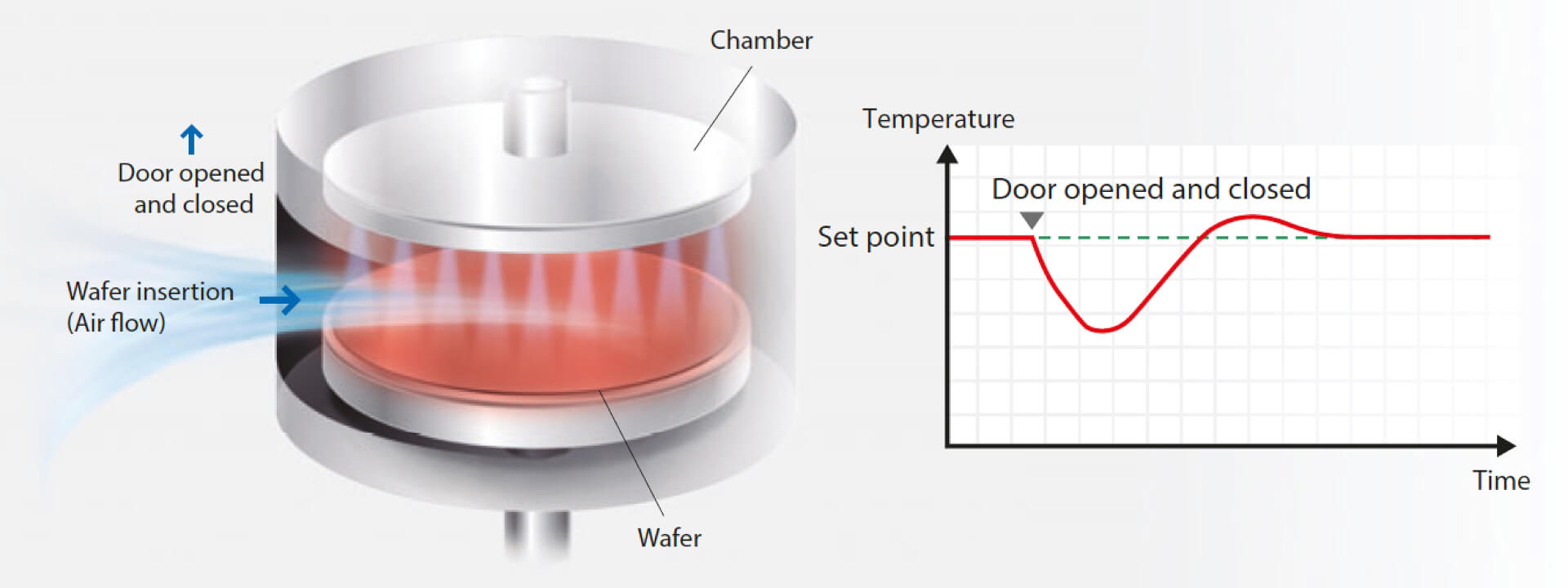

The advanced packaging and high integration of semiconductors have made stringent temperature control a must. Routine disturbances cause temperature variations that impact quality. The waiting time until temperature variations, caused by routine disturbances, stabilize hampers improvements in production capacity.

Our solution: Advanced temperature control

The Disturbance Suppression Function is a control function that automatically suppresses temperature variations that are expected to be caused by foreseeable disturbances. Trigger signals input to the temperature controller before these disturbances occur turn the function on, which adds to or subtracts from the manipulated variable (MV). Disturbance autotuning automatically adjusts the FF (feedforward) MV, FF operation time, and FF waiting time.

NX-HTC and NX-TC temperature control units, provide stable automatic control against foreseeable temperature variations, e.g. those caused by outside air infiltration when doors are opened and closed. NX-HTC and NX-TC contribute to quality improvement and help boost production capacity by reducing the wait time until temperature stabilization.

Enabling Technologies

Related Products

Information & Productivity in a miniaturized size controller

The NX1 series modular machine controller provides logic sequence, motion and information functionality. NX1 is joining production and IT worlds, minimizing engineering and maintenance while suppressing middleware.

Next generation of controllers

NX-TC is next generation controllers designed to achieve optimal and automatic temperature control without human intervention. NX-HTC makes one step further to prevent anomalies due to wrong machine assembly/maintenance and reduce man-hours spent to analyzing and fixing anomalies.

Modular IP20 IOs

Considering IOs as one of the fundamental ingredients for automation, NX Series offers full portfolio of IO slides and couplers providing added values and unique features in the market. Thanks to NX Series, Omron proposes a complete range of automation products, from the sensor level to the controller side and beyond. Main features in a flash:

Do you want to know more?

Contact Our Experts

Contact me Temperature Control for Wafers

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

Download