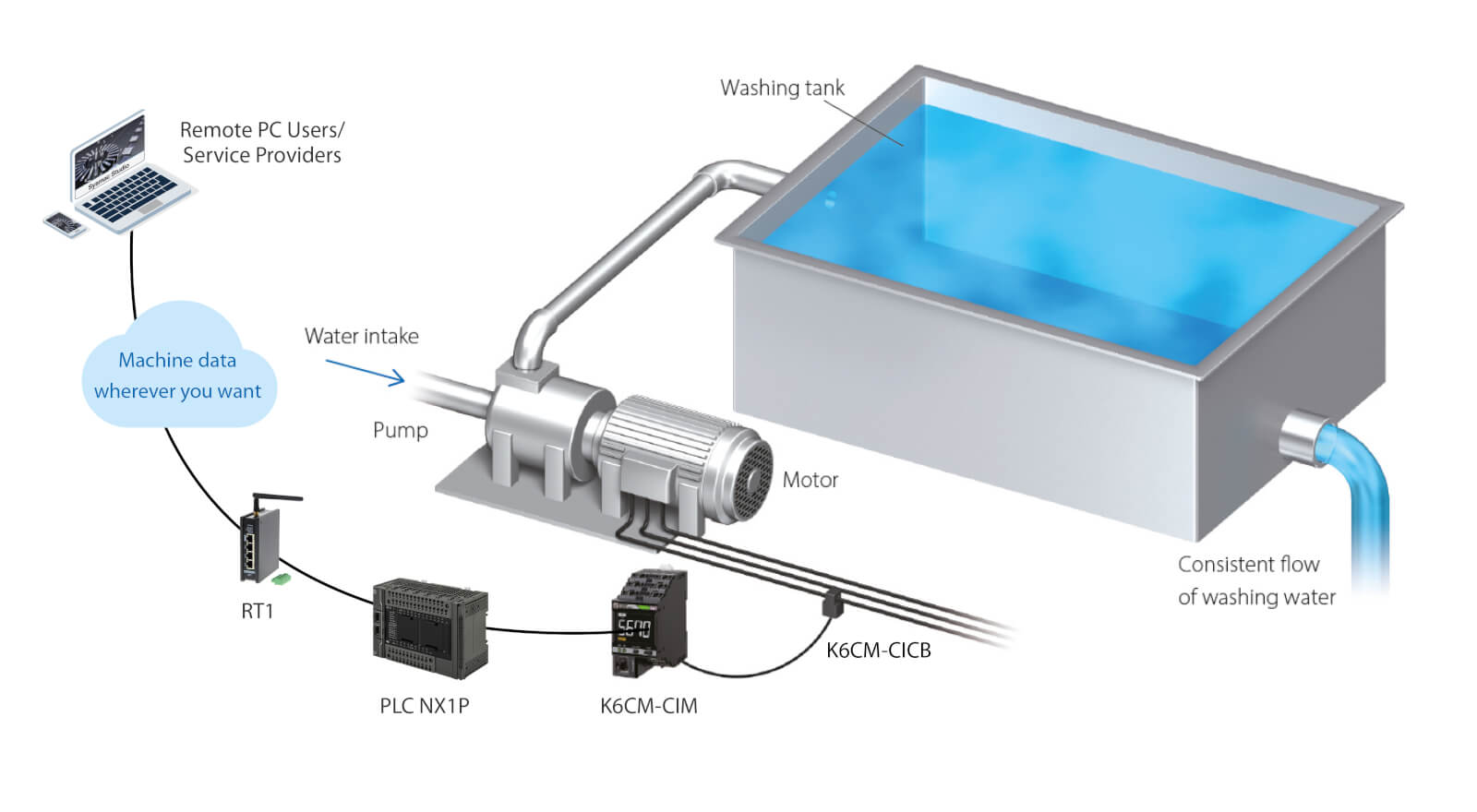

Avoid pump cavitation by detecting air in the system and ensure a consistent flow of water.

Washing water is pumped with a motor-driven pump to a washing tank. However, pockets or cavities can form in the process, resulting in pump cavitation. Pump cavitation can be described as the creation and collapse of the air bubbles in a fluid. When the air bubble enters the pump, it causes an air lock. It is not always possible to have safe access to the pump station due to adverse weather conditions, hazardous locations or security measures.

Interested?

Download our whitepaper “Three tips for smarter maintenance in the water processing industry”

LEVEL 1: Generate self-explanatory Maintenance information

OMRON components, sensors and actuators are designed to provide Realtime system health information.

LEVEL 2: Elaborate Maintenance Data and information at the edge

Elaboration is done at machine level for quick reaction time and alerts.

LEVEL 3: IoT enabler and Secure remote access

Reduced Spend on Site Maintenance Visits and cost optimisation.