Notification module

Information from the sensors or pre elaborated in the controller can trigger alerts and alarms, via e-mail, SMS or social media like telegram to the right people for a quick intervention. Customized Messages contain all the required pieces of info needed to reduce maintenance time.

Data collection and treatment

Omron Controller can collect and analyze maintenance information generated at sensor level. A FB library to read data directly from Omron sensors and actuators reduce programming time. Data analytics and treatment is provided at the edge in the PLC with simple functions to find symptom-cause relation.

Data export

Raw or pre-elaborated data can be exported and integrated in an existing database or service in cloud. Several protocols for OT/IT connectivity are provided in the Omron controller: SQL including stored procedures, OPC-UA, MQTTs, HTTPs, Ethernet IP as well PackML Companion Specification for OPC UA.

Root cause identification

Unique Automation Playback function provides the possibility to go back on time to easily find the cause of the unexpected behaviour. Recorded video, ladder program and data waveforms are stored without compromising the production performance.

Download our leaflets “Smart maintenance ideas and solutions’’ to learn more

Back to Smart Maintenance

Maintenance is a vital to assuring 24/7 operations. Even the failure of a single component can have a massive impact on operations, while energy and maintenance expenses are a major part of the lifecycle costs of automatic machines

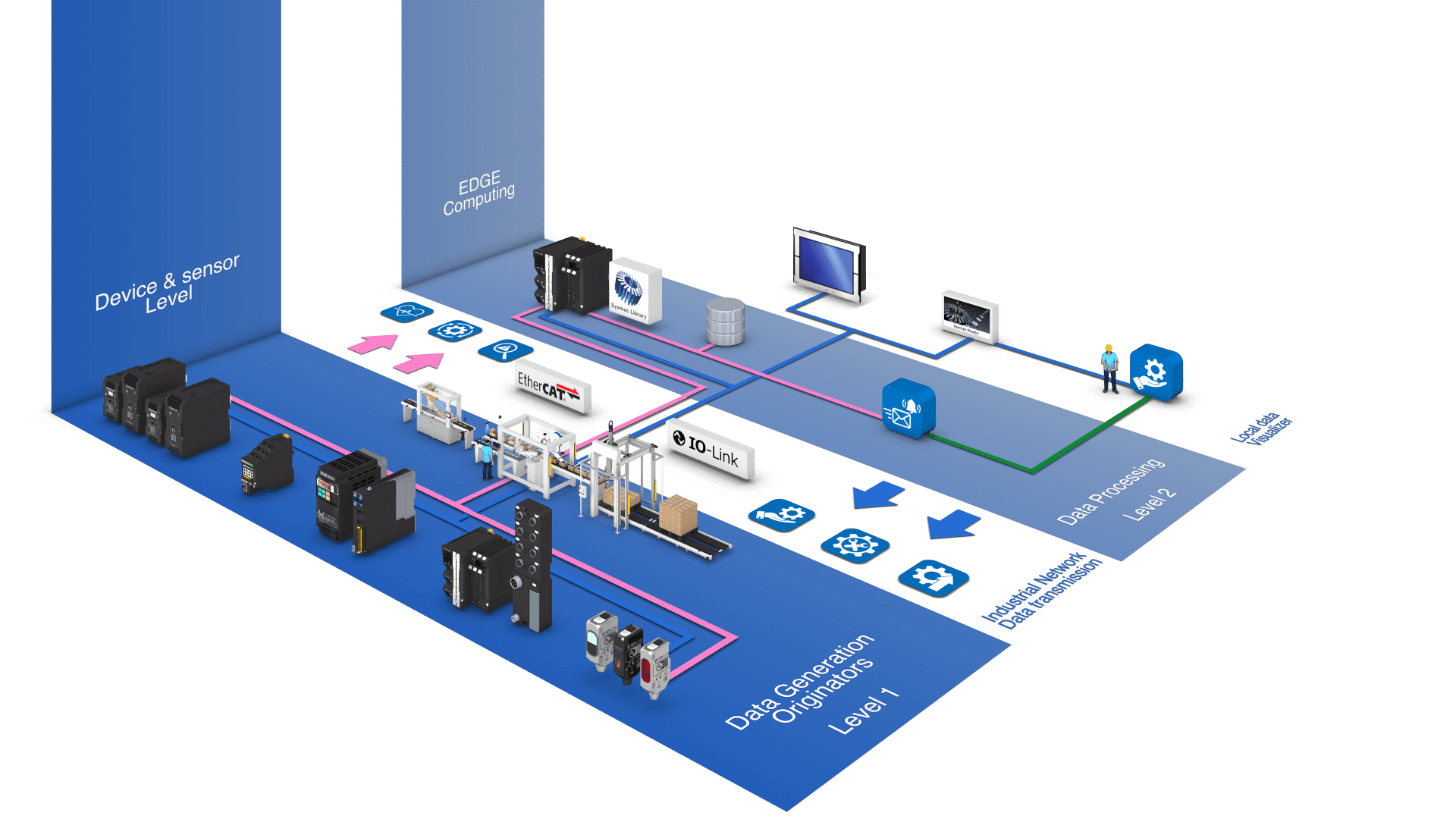

LEVEL 1: Generate self-explanatory Maintenance information

OMRON components, sensors and actuators are designed to provide Realtime system health information.

LEVEL 3: IoT enabler and Secure remote access

Reduced Spend on Site Maintenance Visits and cost optimisation.