LD-series

Fully Autonomous Mobile Robots

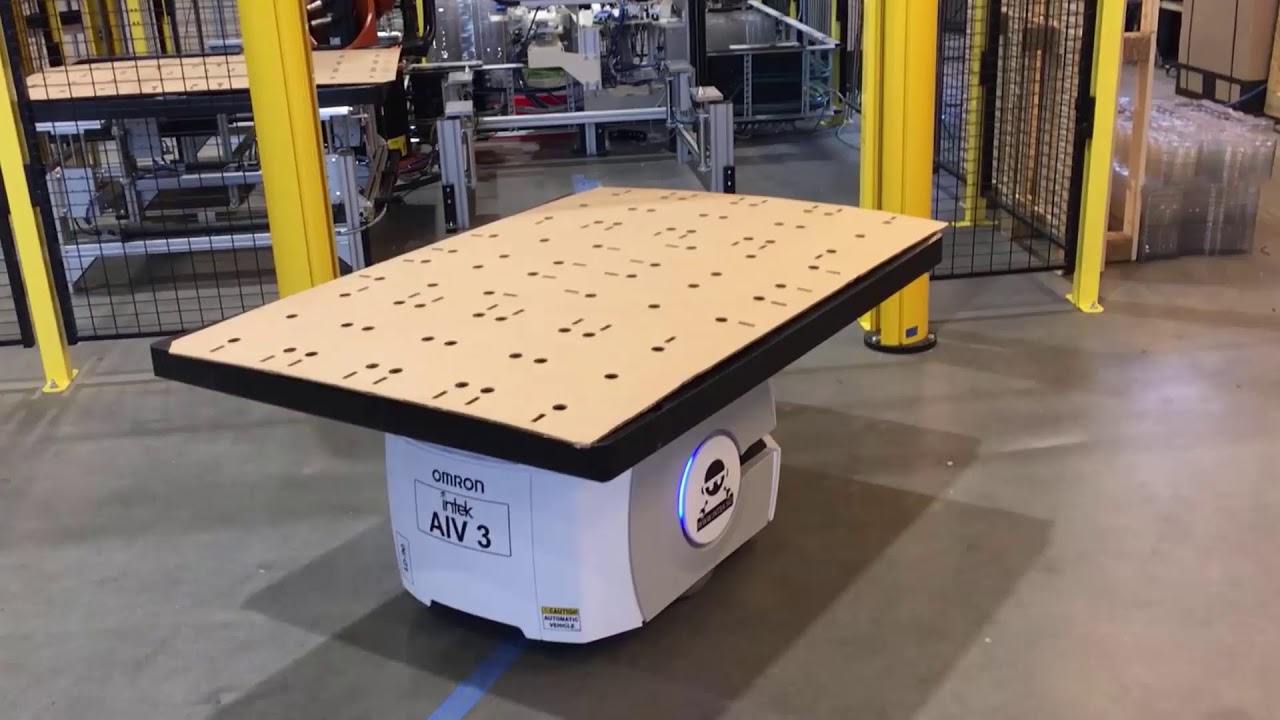

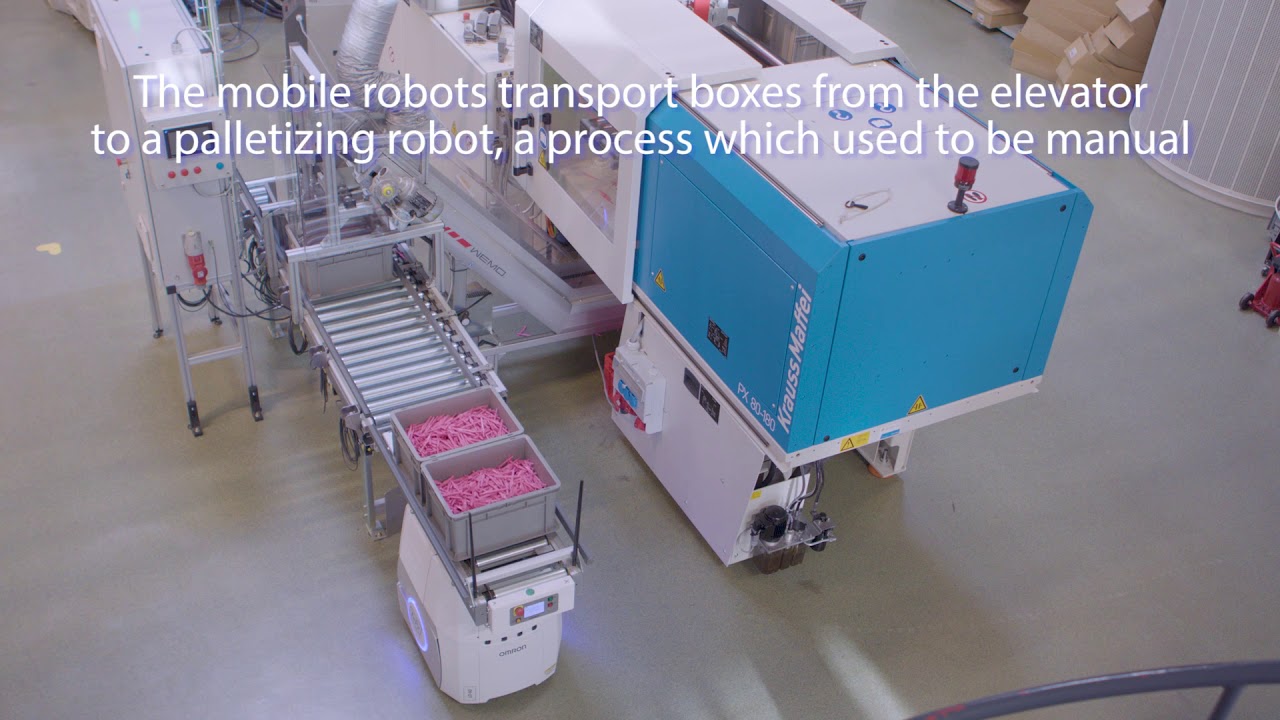

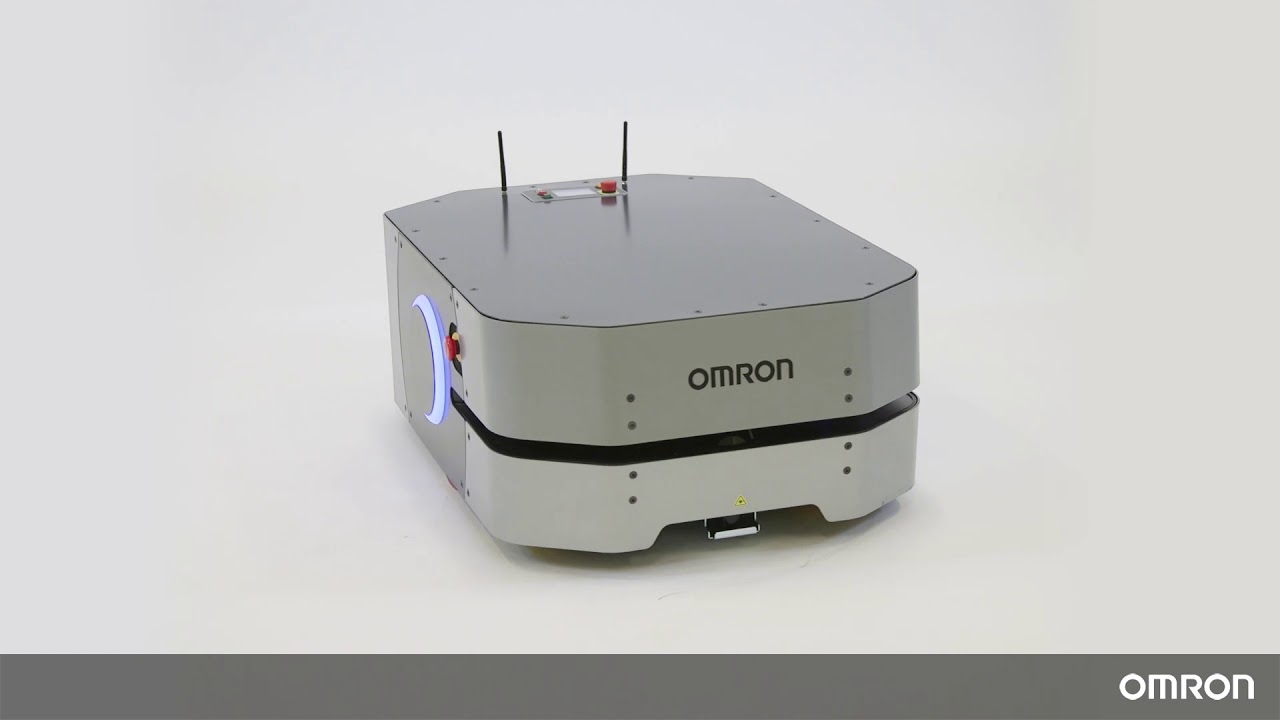

OMRON mobile robots are autonomous mobile robots (AMRs) designed to dramatically increase productivity in manufacturing and logistics operations. Our mobile robots increase throughput, eliminate errors, improve material traceability, and allow employees to focus on tasks that require complex human skills. What’s more, unlike traditional AGVs, our mobile robots navigate by the natural features of the facility and require no expensive facility modification.

-

Omron mobile robots

Omron's Autonomous Mobile Robots (AMRs): no facility modifications, no laser beacons, no floor magnets, no tapes and setup the robot within an hour.

01:49

Omron mobile robots

Omron's Autonomous Mobile Robots (AMRs): no facility modifications, no laser beacons, no floor magnets, no tapes and setup the robot within an hour.Self-navigating Autonomous Mobile Robot (AMR)

LD-series Mobile Robot Datasheet

Features

Easy installation

-

1Easy Decisions & Lower CostsOMRON provides subscription model that offer lower initial cost and ongoing upgrades and improvements to service of functions. Customer can make decisions more easily.

-

2Select Apps and ToppersOMRON has several success cases involving toppers; OMRON sales can advice customers on the best solutions.

-

3Mapping and Goal SettingAfter a short tour through your facility, the robot will make a custom map of your floor plan and set up goals for pick-ups and drop-offs.

-

4Easy OperationSimple operation by tablet and simple integration between the OMRON Fleet Manager and your MES and WMS allows you to get your robots working immediately.

Safety features

-

1Avoids static and moving obstacles

-

2Additional E-stops easily added

-

3Complies with ISO EN1525, JIS D6802 and ANSI B56.5 safety standards

Technology

AMR Technology and Software

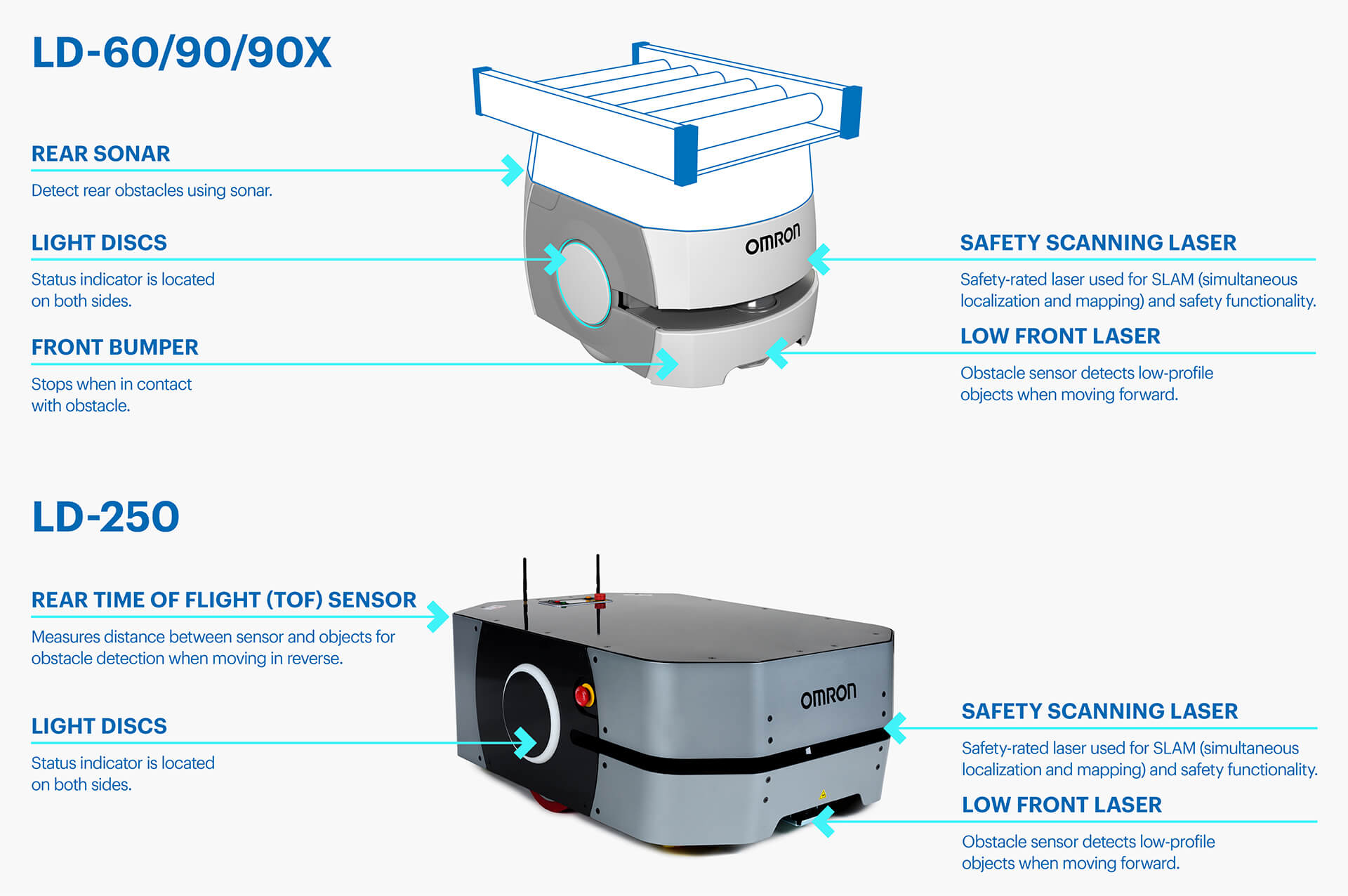

OMRON's Autonomous Mobile Robots (AMRs) are equipped with dedicated AMR technology for navigation and alignment positioning. This technology allows the AMRs to move safely and efficiently within their designated workspaces, even in complex environments. The AMRs are also operated by software, which makes them easy to use and program.

- The dedicated AMR technology used by OMRON's AMRs includes a variety of sensors, such as laser scanners, which allow the robots to accurately map their environment and navigate safely.

- The software used to operate OMRON's AMRs is user-friendly and intuitive, making it easy to program the robots to perform specific tasks.

Robust Navigation

-

Omron's LD mobile robots automate material transport and increase efficiency - full version

Handling high-mix and low volume production, whilst compensating labour shortage are challenges for Omron manufacturing in Japan. See how LD mobile robots are used to automate material transport and increase efficiency, to accelerate human-machine collaboration.

03:47

Mobile robots smarten up Toyota’s new parts centre

Models

LD-60, LD-90, and LD-90x platforms

Our OEM mobile platform is available to developers for custom applications and payloads. It includes our proprietary self-navigation software, which is ideal for use in crowded environments, tight hallways, and applications where a compact automated vehicle is advantageous. Our OEM partners and payload developers enjoy access to a reliable drive system, an on-board power supply, automated self-charging, and I/O for integrating payload hardware onto the mobile platform.

Our OEM mobile platform is available in three configurations, both with a runtime of up to 19 hours a day:

- LD60 capable of transporting up to 60kg (max speed 1.8 m/s)

- LD90 capable of transporting up to 90kg (max speed 1.35)

- LD-90x, use it in a Cart Transporter configuration to increase maximum payload up to 170 kg (max. speed 0.9 m.s)

LD-250 platform

- LD-250 capable of transporting up to 250kg (max speed 1.2 m/s)

LD-250 Leaflet

-

Bigger, stronger, better: new LD-250 mobile robot from Omron moves payloads up to 250kg

The new LD-250 mobile robot from Omron can handle a payload of 250kg and is the strongest and newest addition to our LD series of mobile robots. Together with the Fleet Manager, which for the first time in the industry enables the control of multiple mobile robots with different payloads through one system, it will help realize a more flexible and optimized autonomous material transport system.

02:37

LD-60/90/90x/250 ESD platforms

The ESD robots are designed for complex production environments allowing you to expand your automated material handling applications while staying protected. Designed to provide protection for your Electrostatic Discharge Sensitive (ESDS) products.

The ESD skins create a protective shield around the robot that not only protect your investment, but they also safely dissipate static energy to the ground. With the LD-series ESD mobile robots, we provide a safe solution for handling static sensitive components.

- Joint protection for your “Electrostatic Discharge Sensitive (ESDS)” products and the LD-series.

- Complies with IEC 61340-5-1 as static controlled surfaces with Rg < 1 x 10^9.

- Protection for field strengths above approximately 40 kV/cm of air.

- Skins designed to resist the static build-up.

LD-250 ESD Leaflet

Specifications & ordering info

| Product | Mobile robot type | Maximum load | Maximum speed | Kit type | ESD protection | Battery included | Description | |

|---|---|---|---|---|---|---|---|---|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot | No | No | Mobile Robot, LD-60, without Battery |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + docking kit | No | No | Mobile Robot Docking Station Kit, LD-60, Charger, without Battery |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + starter kit | No | No | Mobile Robot Starter Kit, LD-60, with Charger, without Battery, Joystick, Top Plate |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot | Yes | No | Mobile Robot, LD-60, ESD, without Battery |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + docking kit | Yes | No | Mobile Robot Docking Station Kit, LD-60, ESD, Charger, without Battery |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + starter kit | Yes | No | Mobile Robot Starter Kit, LD-60, ESD, without Battery, with Charger, Joystick, Top Plate |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot | No | No | Mobile Robot, LD-90, without Battery |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + docking kit | No | No | Mobile Robot Docking Station Kit, LD-90, Charger, without Battery |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + starter kit | No | No | Mobile Robot Starter Kit, LD-90, with Charger, without Battery, Joystick, Top Plate |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot | Yes | No | Mobile Robot, LD-90, ESD, without Battery |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + docking kit | Yes | No | Mobile Robot Docking Station Kit, LD-90, ESD, Charger, without Battery |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + starter kit | Yes | No | Mobile Robot Starter Kit, LD-90, ESD, without Battery, with Charger, Joystick, Top Plate |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot | No | No | Mobile Robot, LD-90x, without Battery |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + docking kit | No | No | Mobile Robot Docking Station Kit, LD-90x, Charger, without Battery |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + starter kit | No | No | Mobile Robot Starter Kit, LD-90x, with Charger, without Battery, Joystick, Top Plate |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot | Yes | No | Mobile Robot, LD-90x, ESD, without Battery |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + docking kit | Yes | No | Mobile Robot Docking Station Kit, LD-90x, ESD, Charger, without Battery |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + starter kit | Yes | No | Mobile Robot Starter Kit, LD-90x, ESD,without Battery, with Charger, Joystick, Top Plate |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot | No | No | Mobile Robot, LD-250, without Battery |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot + docking kit | No | No | Mobile Robot Docking Station Kit, LD-250, with Charger, without Battery |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot + starter kit | No | No | Mobile Robot Starter Kit, LD-250, with Charger, Joystick, Top Plate, without Battery |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot | Yes | No | Mobile Robot, LD-250, ESD, without Battery |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot + docking kit | Yes | No | Mobile Robot Docking Station Kit, LD-250, ESD, with Charger, without Battery |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot + starter kit | Yes | No | Mobile Robot Starter Kit, LD-250, ESD, with Charger, Joystick, Top Plate, without Battery |

|

We've got a nearly-infinite combination to fit any production scenes.

Interested?

Contact me LD-series

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for LD-series

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadAccessories

Filter on

TEG AMR212 Conveyor Top - Front Belt

Tecno Electric Girona

TEG AMR221 Conveyor Top - Side Belt

Tecno Electric Girona

TEG AMR231 Conveyor Top - Front Roller

Tecno Electric Girona

TEG AMR241 Conveyor Top - Side Roller

Tecno Electric Girona

Belt Conveyor Top Module LD-250-BC-CW

Dimalog Oy

Belt Conveyor Top Module LD-250-BC-LW

Dimalog Oy

Belt Conveyor Top Module LD-60/90-BC-CW

Dimalog Oy

Belt Conveyor Top Module LD-60/90-BC-LW

Dimalog Oy

Next

Applications & Key Industries

-

Intralogistics process and related challenges

OMRON solution for the complete intralogistics process The complete intralogistics process in a factory is divided into four different groups because the challenges are different, but also the solutions: Lineside Replenishment; Work in progress; Finished goods and Warehouse. Read more on:

03:18

OMRON solution for the complete intralogistics process

Customer Cases

-

Mobile robots streamline internal logistics at HIPRA

Autonomous mobile robots increase the flexibility, efficiency, and productivity of material transport. HIPRA, a pioneering biotechnological company in the pharmaceutical industry, has transformed its internal logistics processes by installing a fleet of mobile robots supplied by OMRON. Read more:

03:30

Mobile robots streamline internal logistics at HIPRA

Autonomous mobile robots increase the flexibility, efficiency, and productivity of material transport. HIPRA, a pioneering biotechnological company in the pharmaceutical industry, has transformed its internal logistics processes by installing a fleet of mobile robots supplied by OMRON. Read more:

-

Operators and robots work in harmony: Grupo Antolin automates handling of car interior components

Major trends in the automotive industry – including an increasing emphasis on issues such as electrification, digitalization, and sustainability – are also driving changes in vehicle interiors. One of the largest international players in this sector is Grupo Antolin. As a key player at global automotive supply chain and high value manufacturing leader, the strategy of the company, Adv. Manufacturing 4.0, looks into integration of digital technology in the operations. One of the focus areas is the reduction and optimization of movements in internal logistic. Introducing autonomous mobile robots (AMRs) and collaborative robots (cobots), manufactured and supplied by OMRON, helps achieve a modernized and more sustainable factory where people and machines are working in harmony. For more information, visit:

03:11

Operators and robots work in harmony: Grupo Antolin automates handling of car interior components

Major trends in the automotive industry – including an increasing emphasis on issues such as electrification, digitalization, and sustainability – are also driving changes in vehicle interiors. One of the largest international players in this sector is Grupo Antolin. As a key player at global automotive supply chain and high value manufacturing leader, the strategy of the company, Adv. Manufacturing 4.0, looks into integration of digital technology in the operations. One of the focus areas is the reduction and optimization of movements in internal logistic. Introducing autonomous mobile robots (AMRs) and collaborative robots (cobots), manufactured and supplied by OMRON, helps achieve a modernized and more sustainable factory where people and machines are working in harmony. For more information, visit:

-

Mobile order preparation and operator support solution from Savoye with OMRON mobile robots

The Mobile Robot solution from Savoye is a flexible and economical alternative to manual processes. Mobile robots move autonomously, carrying packages and items to the various areas of the warehouse, allowing operators to be freed from: - Routes between launching area, picking areas and packaging areas - Fatigue generated by cart handling activities The operators remain in their picking area, thus devoting their time to value-added operations. The Savoye Mobile Robot solution can be used in stand-alone mode, independently interfaced with Savoye WMS and WCS software, or in addition to an automated system. There are many use cases, all relying on the same IT architecture: - Multi-package preparation (pick & pack), - Item picking before splitting (pick-then-pack) - Replenishment of retail picking locations For more information, please visit:

03:32

Mobile order preparation and operator support solution from Savoye with OMRON mobile robots

The Mobile Robot solution from Savoye is a flexible and economical alternative to manual processes. Mobile robots move autonomously, carrying packages and items to the various areas of the warehouse, allowing operators to be freed from: - Routes between launching area, picking areas and packaging areas - Fatigue generated by cart handling activities The operators remain in their picking area, thus devoting their time to value-added operations. The Savoye Mobile Robot solution can be used in stand-alone mode, independently interfaced with Savoye WMS and WCS software, or in addition to an automated system. There are many use cases, all relying on the same IT architecture: - Multi-package preparation (pick & pack), - Item picking before splitting (pick-then-pack) - Replenishment of retail picking locations For more information, please visit:

-

Material handling solutions with autonomous mobile robots

LCS has implemented applications with OMRON autonomous mobile robots in various markets and industries that require efficient, flexible and automated logistics. LCS Group has been operating on the Italian and European markets since 1989 as a System Integrator, offering complete, integrated and cutting-edge hardware and software solutions for internal logistics, airports and industrial automation. Music in this video Inspirational Corporate Ambient Artist: Aleksandr Shamaluev Album: Corporate Music Licensed to YouTube by HAAWK for a 3rd Party (on behalf of AShamaluevMusic); HAAWK Publishing, BMI - Broadcast Music Inc., and 3 music rights societies

02:36

Material handling solutions with autonomous mobile robots

LCS has implemented applications with OMRON autonomous mobile robots in various markets and industries that require efficient, flexible and automated logistics. LCS Group has been operating on the Italian and European markets since 1989 as a System Integrator, offering complete, integrated and cutting-edge hardware and software solutions for internal logistics, airports and industrial automation. Music in this video Inspirational Corporate Ambient Artist: Aleksandr Shamaluev Album: Corporate Music Licensed to YouTube by HAAWK for a 3rd Party (on behalf of AShamaluevMusic); HAAWK Publishing, BMI - Broadcast Music Inc., and 3 music rights societiesVideos

-

Mobile Manipulator combines a cobot arm with an autonomous mobile robot for flexible production

OMRON's autonomous mobile manipulator solution supports flexible manufacturing and improves efficiency by integrating a self-navigating LD mobile robot with OMRON's collaborative robot arm. What will you use it for?

01:43

Mobile Manipulator combines a cobot arm with an autonomous mobile robot for flexible production

OMRON's autonomous mobile manipulator solution supports flexible manufacturing and improves efficiency by integrating a self-navigating LD mobile robot with OMRON's collaborative robot arm. What will you use it for?

-

OMRON FLOW Core 3.0 MobilePlanner

Our MobilePlanner allows you to easily and effectively utilize fleets of heterogeneous robot types alongside one another to optimize their automation solution. MobilePlanner expands our Fleet Management ecosystem as the best in the industry. #omronindustrialautomation #mobilerobots

00:53

OMRON FLOW Core 3.0 MobilePlanner

Our MobilePlanner allows you to easily and effectively utilize fleets of heterogeneous robot types alongside one another to optimize their automation solution. MobilePlanner expands our Fleet Management ecosystem as the best in the industry. #omronindustrialautomation #mobilerobots

-

OMRON FLOW Core 3.0 Selectable Autonomy

Enables users to tailor traffic flow with powerful path modes, ranging from autonomous guided vehicle (AGV)—but without the costly infrastructure—to limited detour windows, to the pure flexibility of a traditional AMR. #omronindustrialautomation #mobilerobots

01:09

OMRON FLOW Core 3.0 Selectable Autonomy

Enables users to tailor traffic flow with powerful path modes, ranging from autonomous guided vehicle (AGV)—but without the costly infrastructure—to limited detour windows, to the pure flexibility of a traditional AMR. #omronindustrialautomation #mobilerobots

-

Omron Mobile Planner Tablet Edition - Intro

Introduction of the Omron Mobile Planner - an easy to use, portable, monitoring and control user interface tool for LD Mobile Robots.

03:21

Omron Mobile Planner Tablet Edition - Intro

Introduction of the Omron Mobile Planner - an easy to use, portable, monitoring and control user interface tool for LD Mobile Robots.Downloads

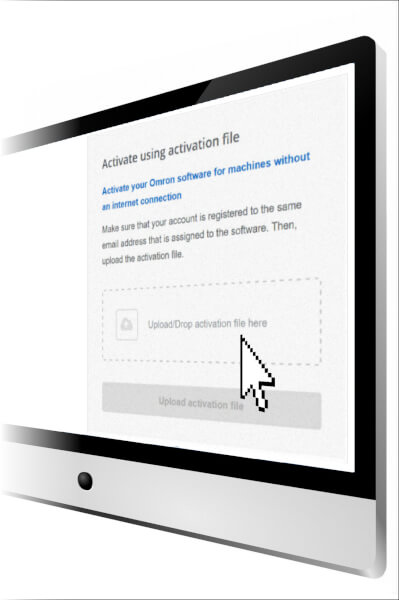

Activate your Mobile Robot Software

Solutions

Fleet Simulator - Optimize your fleet before you deploy it

OMRON Fleet Simulator offers the industry’s first mobile robot simulator for factory and manufacturing applications.

Omron Mobile Manipulator Solution

The unique cobot and mobile robot hybrid concept solution from OMRON

OMRON Fleet Simulator offers the industry’s first mobile robot simulator for factory and manufacturing applications

Services

How can we help you?

If you have a question or would like to ask for a quote, please contact us or send a request.

Contact me LD-series

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for LD-series

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

Download

_reference_manual_en.jpg)

_leaflet_en.jpg)