Customer references

At Omron, we like to listen to our customers. We could spend all day listening to their needs – it gives us ideas. And because we’ve been listening to our packaging machine customers for more than 20 years, you won’t be surprised that we’ve had quite a lot of good ideas.

But rather than us tell you about them, we thought you would prefer hearing it from people like you: our customers.

FG Robosys

FG Robosys, a leader in providing robotic solutions for the cosmetic and personal care industries, decided to enhance their robotic bottling line to improve efficiency and reduce changeover times at their customers’ production facilities.

Automated Solution for Case Erector Loading: Coboloader from Inser Robótica

Improving the end-of-line efficiency and ergonomics with a collaborative robotic cell

Watch video on an innovative anti-sloshing solution for soup and ready meal packaging

Italian Pack and OMRON have joined forces to introduce Argo, an automatic tray sealing machine equipped with an innovative anti-sloshing system

Picomel looks to the future with a visionary production line

Vertical factory saves space and energy while reducing waste

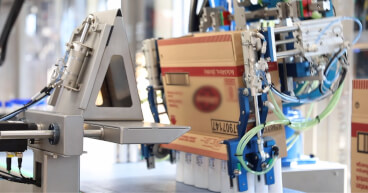

Ricciarelli ensures the perfect closure of spaghetti packaging

The new horizontal cartoning machine for long pasta utilizes OMRON's vision systems to verify the effective closure of the packaging and perfect OCR/OCV marking.

Bandall streamlines banding machines for sustainable packaging

One stand-alone solution with OMRON sensors covers various banding needs

Keeping up with high demand for vegan ice cream with collaborative robotics

Ice Bakers automates end-of-line packaging process with an OMRON TM cobot

MACCO boosts productivity and innovation in packaging lines with OMRON SCARA i4L robot

Optimizing packaging processes for cosmetic, pharmaceutical, and nutraceutical products

Campari Group improves safety worldwide with OMRON Safety

Putting people first: Campari Group improves safety worldwide with OMRON Safety Services. Empowering employees to promote safety from the ground up.

World’s first five-lane bag-in-box machine from Pro Project Machinery

New energy-efficient full servo machine boosts production by 25%

Vetipak enjoys the sweet taste of success thanks to robotics

Packaging solution with robotics integrated control ensures scalable processes and high-quality contract manufacturing in FMCG

Smurfit Kappa Zedek upgrades production line with safety services

A complete one-stop solution from OMRON ensures upgrading the safety of a folder-gluer machine.

Smurfit Kappa Zedek upgrades production line with safety services

A complete one-stop solution from OMRON ensures upgrading the safety of a folder-gluer machine.

Myllyn Paras automates palletizing processes with a collaborative robot

Myllyn Paras, a food manufacturer based in Hyvinkää, Finland, has found an innovative way to automate its palletizing operations.

Adding data to the mix increases productivity by 8%: Cleca improves efficiency with i-BELT

CLECA i-BELT

FlexLink designs a collaborative palletiser for industrial applications

Cobot solution with small footprint and active safety equipment enables handling up to 8 boxes per minute without the need for fencing or laser scanners.

Fit for the future thanks to retrofitting

Machines in food and beverage production have to be reliable, safe, fast, and maintain quality over many years and even decades.

Martini perfects the packaging of pasta with OMRON technology

Based in Italy, Martini Srl produces high-precision weighing and packaging machines for the food sector. Its new MCRS-VD packaging system enables the packaging of up to 180 packs of pasta per minute. At the heart of the solution is an OMRON NX701 1600 machine controller. This manages the movements of the MCRS-VD. OMRON’s NX-TC Perfect Sealing technology enables the end user to improve the stability of the thermoregulation involved and reduces the costs associated with the use of packaging films.

Palletising solution from Reitec meets the needs of FMCG customers

OMRON and Reitec join forces to create the new RC-1 cobot palletiser solution

Agile cobot palletiser from Reeco Automation

60% smaller footprint and costing up to 50% less compared to conventional robot palletisers

Four top tips for automation projects in the food and beverage industry

22 February 2021 Smart, robot-assisted production and packaging will maximize profitability

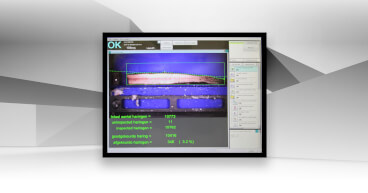

Novio Packaging reaches new levels of quality with machine vision

Inline quality inspection ensures defect-free production of bottles

Unique high-speed seed counting and packing solution by Micron Milling

Overcoming the challenge of accuracy for a large retail group

Automated fish filleting solution ensures quality and cost efficiency at Seafood Parlevliet

The Dutch fish manufacturer achieves 75% reduction in manual labour and up to five times the speed with the automated production line. The solution created by Innovotech BV, a local automation partner, includes control and vision systems from OMRON, and enables the company to preserve competitive production in the Netherlands.

Collaborative robots enhance productivity at CLECA

Palletizing process automated with OMRON TM12 cobots

Factory automation: four tips for the future of food & beverage manufacturing

16 July 2020 The coronavirus pandemic has posed major challenges to organisations of all types and sizes. In the food and commodity industry, companies have faced significantly reduced consumption and disrupted supply chains, while at-home consumption increased, and out-of-home consumption came near to a standstill. But how can manufacturers adapt their business strategies and production processes both now and in the longer term? The pandemic may provide an opportunity for rethinking outdated processes and procedures and enhancing them with concepts such as innovative robotics, sensor technology and holistic automation strategies.

Automation with robotics increases production by 40% at BOLÇİ

Turkish chocolate manufacturer BOLÇİ needed to meet its promise of delivering chocolate products that are ‘untouched by human hand’. Omron and Innovas joined forces to commission a line of three Omron robots in the packaging section of the factory’s production line, with the aim of enhancing production quality and reducing labour costs.

Autonomous bin picking with a collaborative mobile robot

16 October 2019 Our TM collaborative robot provides a unique solution to easily automate applications such as picking and packing that, traditionally performed by humans, have been challenging to automate. As part of the TM series launch, we also released a mobile-compatible model, which seamlessly integrates into Omron’s LD series autonomous mobile robot. Combined with a 3D vision camera mounted directly onto the collaborative robot, this enables for example e-commerce companies to automate more complex tasks. This includes pick and place of various items onto a tray or container, as well as connecting production processes with the autonomous mobile robots for flexible manufacturing and materials handling.

Barcodes: keeping track of product quality

02 October 2019 For many years, barcode technology has proved to be an economical and flexible identification technology. It has continued to develop and as a result, 1D and 2D codes (such as Datamatrix) are now used almost universally. Their versatility have made them a popular choice for streamlining many key supply chain processes, including production, logistics and item traceability.