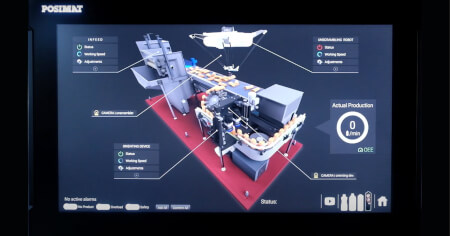

POSIMAT, the Barcelona-based world leading producer of bottle handling systems, brings another innovation to the market with the POSIROBOT. This solution, developed with OMRON's Delta Quattro robots, provides a solution to constant format changes and the complex designs of some bottles. Its delicate handling means that this is a versatile, easy to use, highly flexible and super competitive solution

In response to the growing demand for robotic unscramblers, POSIMAT has launched its POSIROBOT unscrambler to meet the needs of highly competitive and demanding sectors, and thus supply a robotic solution to large industrial companies in different sectors: household cleaning products (home care), cosmetics (personal care), food sector (food), motor oil companies (motor oil), pharmaceutical companies (pharma industry), and in general all companies that need a machine with this technology.

This robotic unscrambler, POSIROBOT, offers great advantages in the positioning sector, which is increasingly critical given the complex designs of some bottles and the need for constant format changes and delicate handling.

As a world leading manufacturer of bottle handling machines with more than 40 years' experience in the packaging sector, POSIMAT has developed its own robotic unscrambler to provide a solution to clients requesting this type of equipment for their production lines.

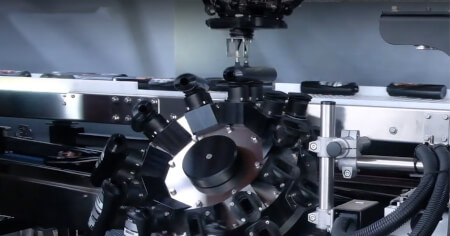

POSIMAT unveiled its robotic unscrambler developed with OMRON's Delta Quattro robots, Artificial Vision and Sysmac Automation Platform. OMRON is a world leader in industrial automation, focused on providing integrated, intelligent and interactive solutions that respond to current market demand in the implementation of highly efficient flexible manufacturing processes. This made it the ideal partner for this project, especially as the two companies have already collaborated on other projects over the last 15 years.

There were several compelling reasons why POSIMAT decided to explore the use of robots for this new unscrambler. These included speed (a single robot handles numerous bottles per minute and more than one robot can be used simultaneously), flexibility (a robotic system capable of handling bottles of any shape or size without the need for mechanical adjustment), and low levels of maintenance (no need for manual interference).

Innovation, experience, optimum cost and maximum efficiency have come together to present a robotic unscrambler that is distinct from other systems on the market and allow it to be marketed as a new, more technically and economically competitive system.