Your Product, Your Image

Our Approach

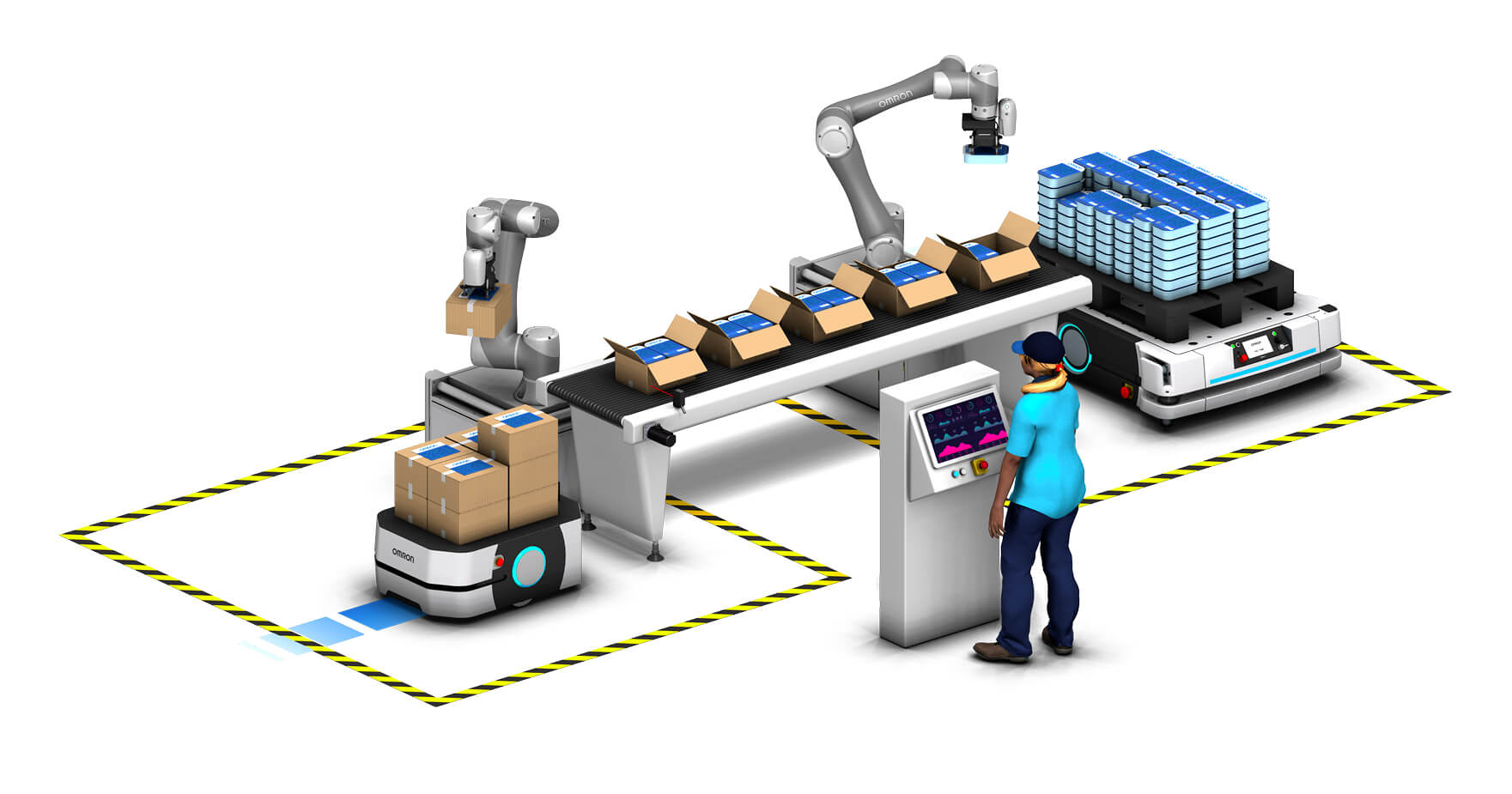

How do you ensure the product reaching the market is the right one and safe to consume? We firmly believe that the answer is to give humans the tasks they do best and to leave the rest to automation. Exchange heavy, boring, and error prone repetitive labour by:

- automated product handling to avoid product contamination

- automated packaging inspection to detect product, packaging, and labelling errors

Our Solution: Automated Handling & Inspection

Benefits of Zero-Touch for Quality

Our Zero-Touch Quality Solution ensures your production organisation:

-

prevents long-term work-related illnesses, injuries and accidents

-

is less vulnerable to non-work related health issues (illnesses, pandemic)

-

eliminates safety concerns around human-machine interaction & exposure

-

reduces public health risks and hygiene issues

-

offers attractive jobs without heavy and repetitive tasks & retains employees

-

is less dependent on job market availability of skilled labour

-

optimises production reliably with fast, consistent, high quality output

Customer Cases

Novio Packaging reaches new levels of quality with machine vision

Inline quality inspection ensures defect-free production of bottles

Automated fish filleting solution ensures quality and cost efficiency at Seafood Parlevliet

The Dutch fish manufacturer achieves 75% reduction in manual labour and up to five times the speed with the automated production line. The solution created by Innovotech BV, a local automation partner, includes control and vision systems from OMRON, and enables the company to preserve competitive production in the Netherlands.

Automated pipetting solution ensures rapid evaluation of Covid-19 samples

GriPS Automation GmbH and D&T engineering GmbH have developed a solution to streamline pipetting, reducing processing time from one hour to ten minutes per plate.

Interesting to Read

Interested in the latest developments? Visit our news blogs for current updates!

Four top tips for automation projects in the food and beverage industry

22 February 2021 Smart, robot-assisted production and packaging will maximize profitability

Affordable automation: Leasing cobots and mobile robots for flexibility on the factory floor

04 March 2021 In line with the move to Industry 4.0, an increasing number of manufacturers are turning to automation as a way of streamlining processes and boosting productivity. A key aspect of this is the use of robots, often working alongside people in the factory. However, many companies might be reluctant to invest in additional automation, particularly following the economic difficulties presented by COVID-19. For manufacturers looking for an affordable solution, cost structures with leasing options are being implemented as an option to allow adaptability on the factory floor.

Automation for zero touch: Improving safety, quality and efficiency in F&B

15 March 2021 Recent innovations in automation, robotics, image processing and artificial intelligence (AI) can help companies to migrate towards zero touch processes.

Related Products

-

Faster machine operation, cameras for every application

-

High-speed, high-accuracy inspection and measurement

-

Sysmac controller – NX7 series

-

Built for the Future of Automation

-

High Resolution Handheld Barcode Reader

-

Parallel robot ideal for use in the food and beverage, pharmaceutical, and healthcare industries