K7GE-MG

Condition Monitoring Device – insulation monitoring

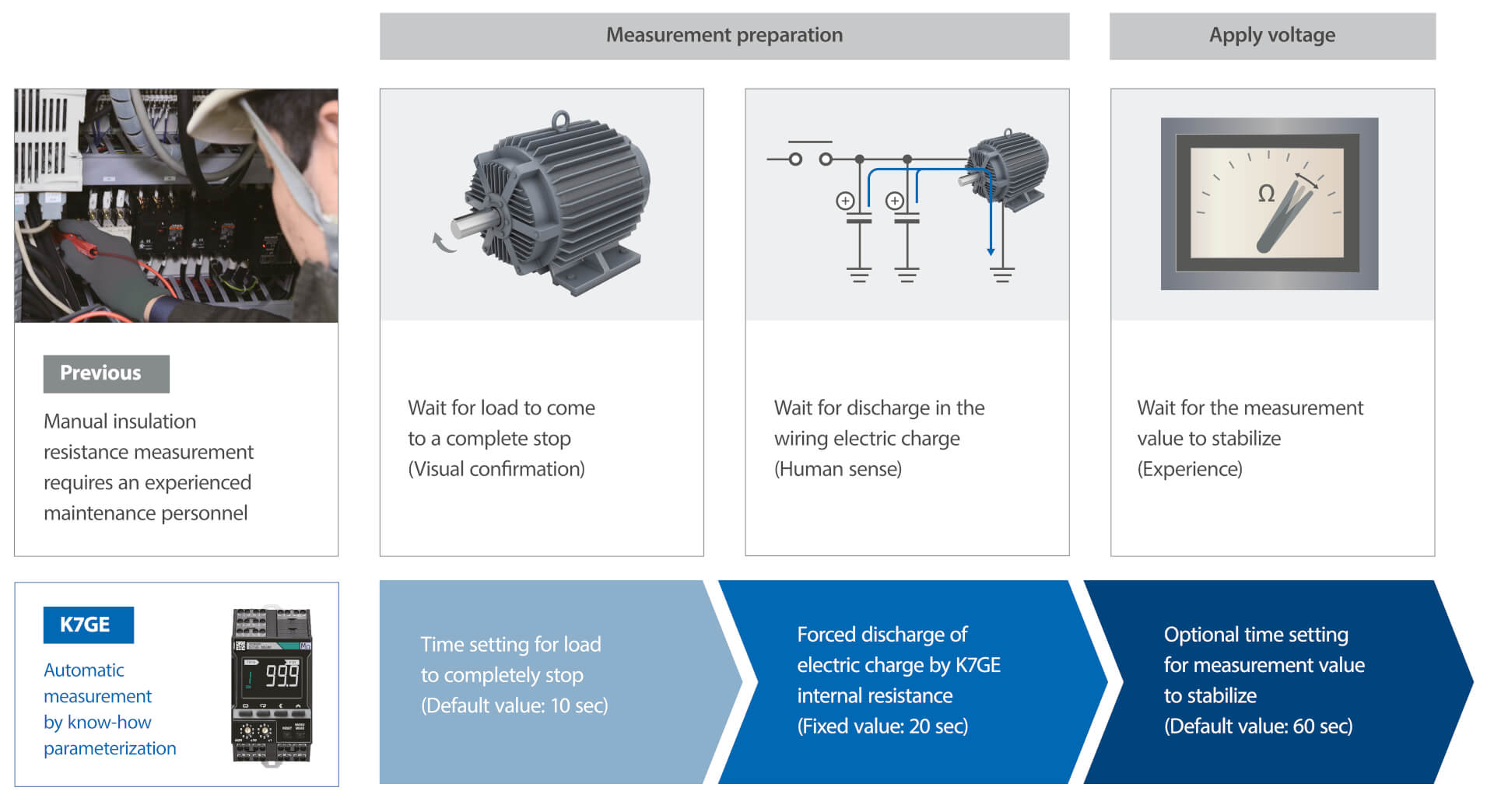

K7GE-MG performs an automatic measurement of the insulation resistance as soon as the device is powered-off, avoiding the need for periodic manual measurement, and allowing to evaluate the deterioration trend of insulation resistance thanks to the increased measurement frequency.

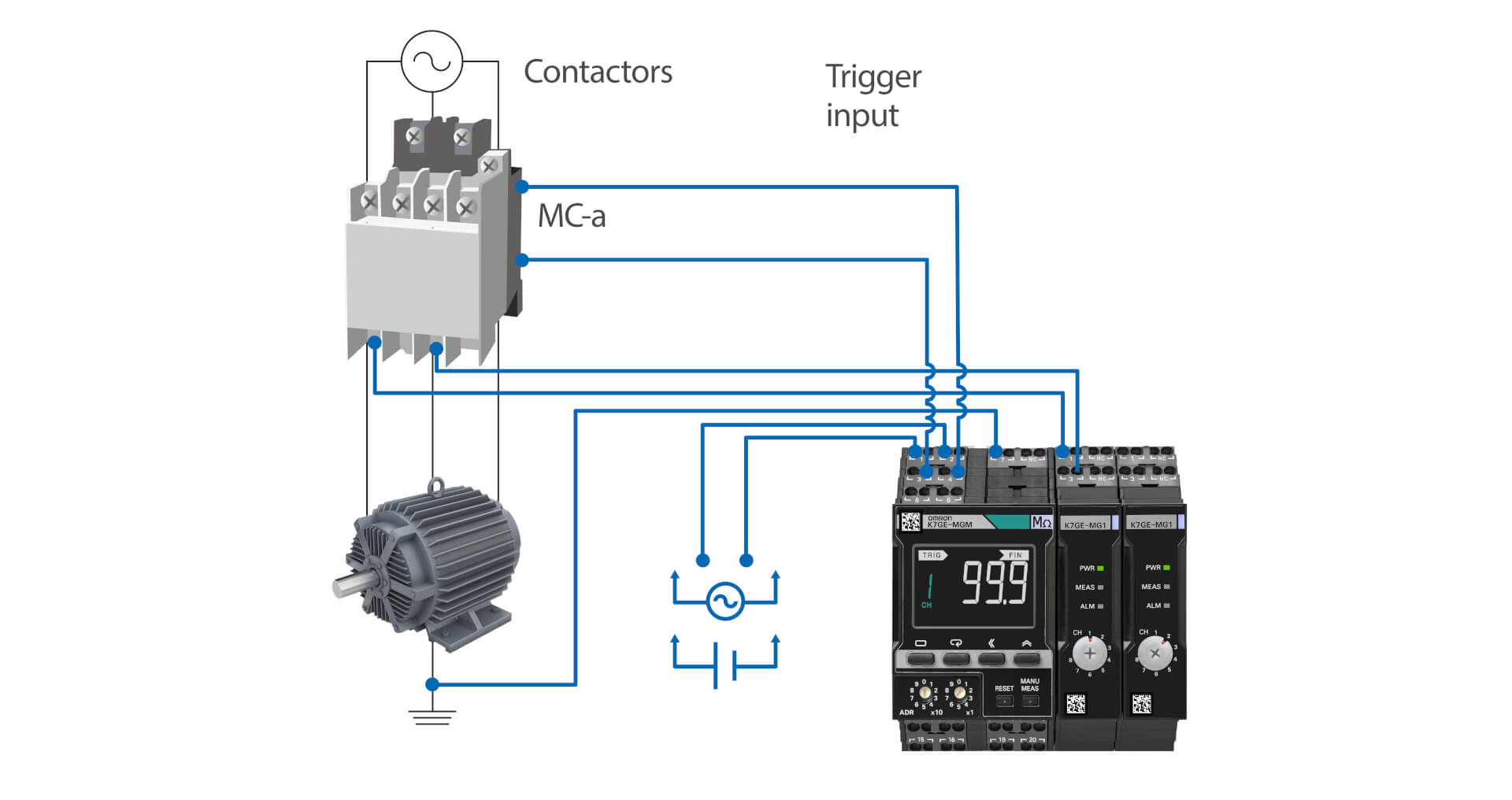

- Automatic insulation measurement when the motor/servo is OFF

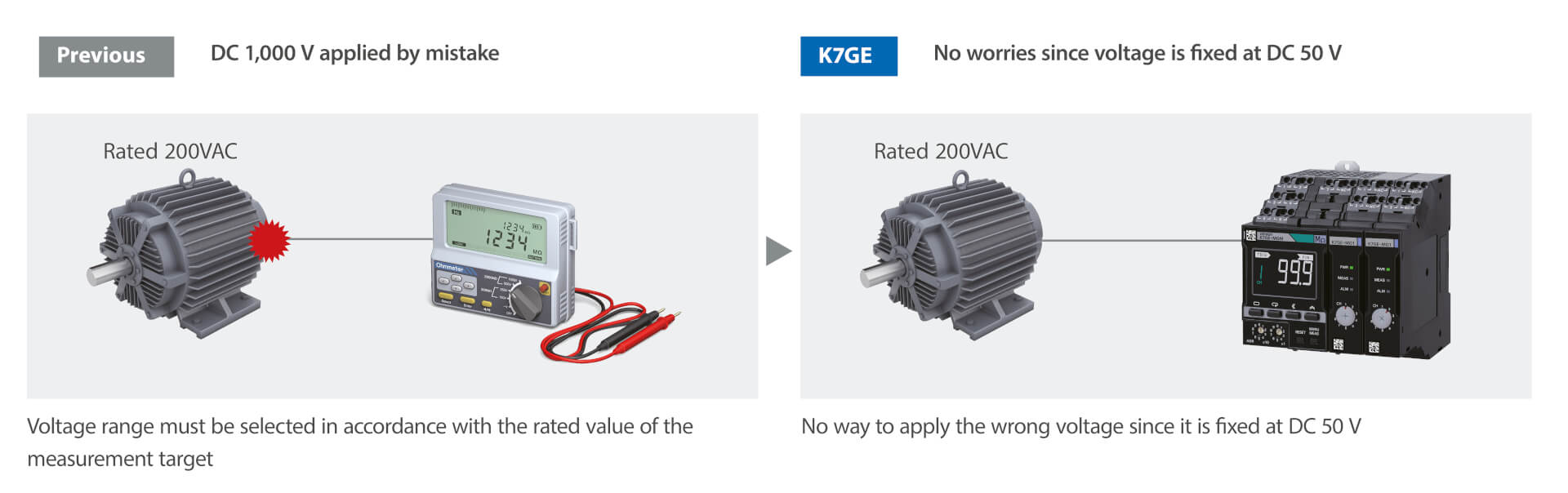

- Low voltage measurement with no overload on the machine equipment

- Easy to install and retrofit

Specifications & ordering info

| Product | Supply voltage AC | Supply voltage DC | Description | |

|---|---|---|---|---|

|

|

100-240 V | Insulation Resistance Monitoring Device for 3-phase & servo motors, pumps and heaters, 100 to 240 VAC, transistor control output, Push-in Plus, LCD display, RS-485/Modbus/RTU |

|

|

|

|

20.4-26.4 V | 20.4-26.4 V | Insulation Resistance Monitoring Device for 3-phase & servo motors, pumps and heaters, 24 VAC/VDC, transistor control output, Push-in Plus, LCD display, RS-485/Modbus/RTU |

|

How can we help you?

If you have a question or would like to ask for a quote, please contact us or send a request.

Contact me K7GE-MG

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for K7GE-MG

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadFeatures

Highly reproducible measurements

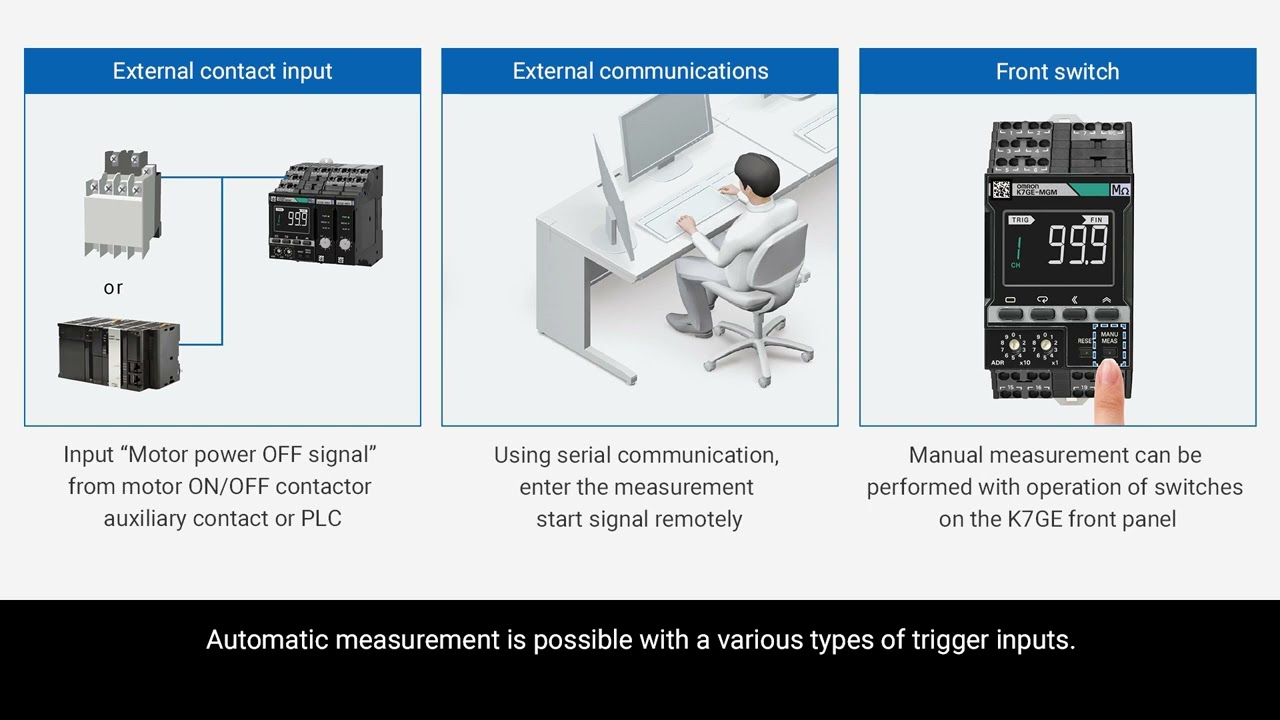

Trend monitoring is not possible if measurement fluctuates due to measurer’s lack of insulation resistance measurement know-how. However, K7GE can contribute to trend monitoring because tasks that cause measurement fluctuation may be set up by parameters, allowing for highly reproducible measurement.

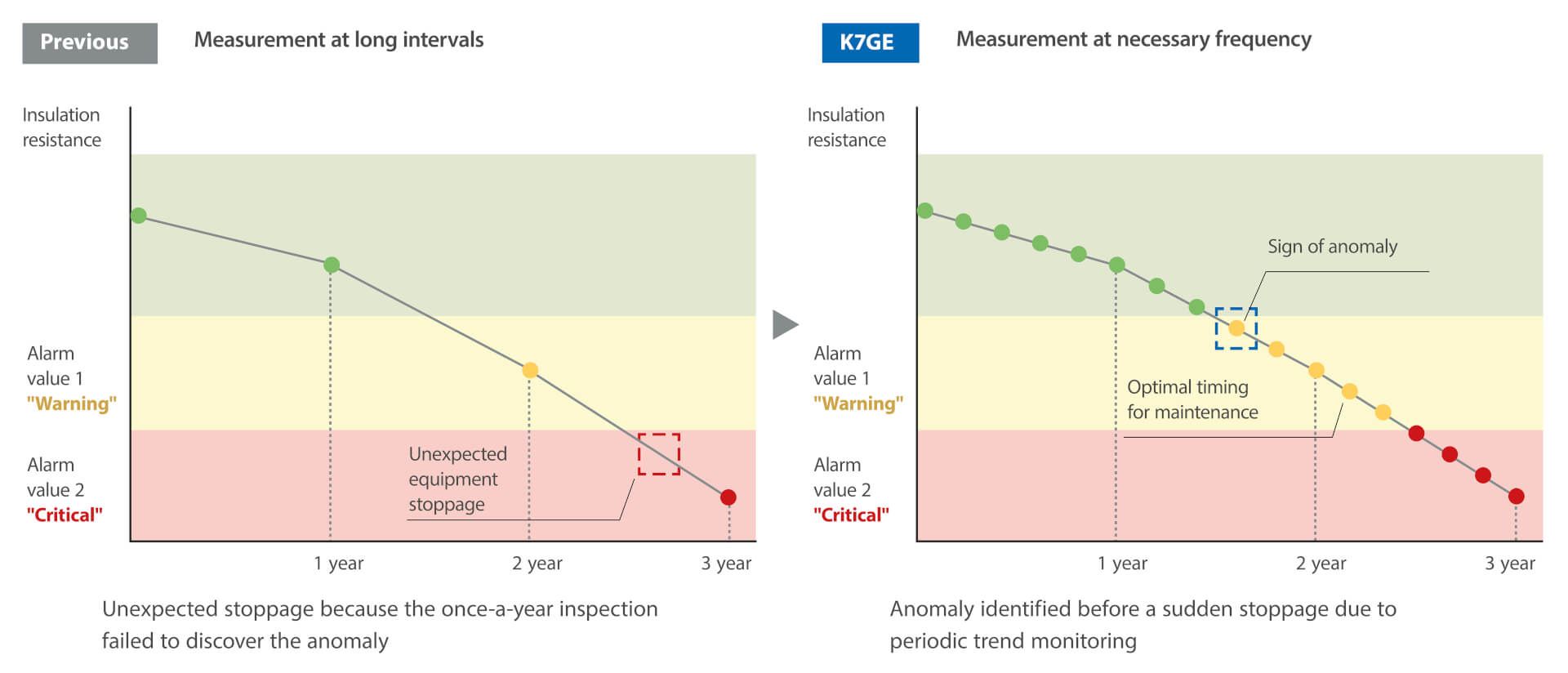

High frequency of measurements to accurately identify equipment abnormalities

K7GE-MG enables automatic measurement that can be repeated every time the device is switched off.This helps avoid sudden stoppages due to insulation degradation which conventional inspections conducted at long intervals may miss.

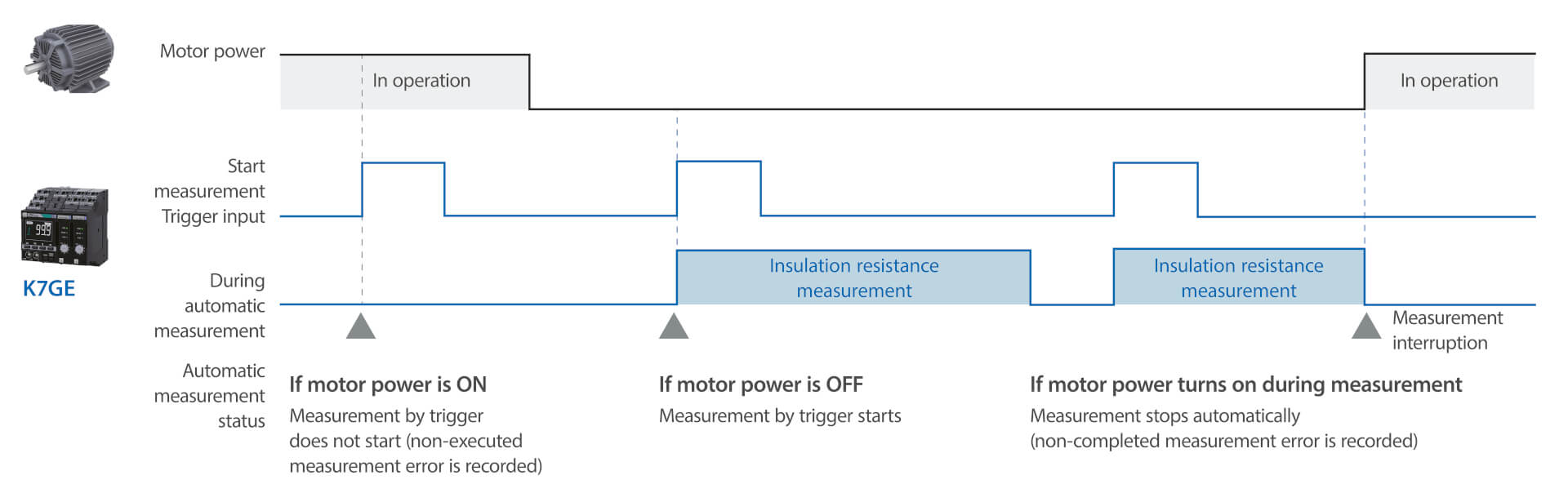

Automatic measurement depends on equipment condition

The automatic measurement eliminates any risk of equipment failure by stopping measurement if the equipment power is restored after its start.

Automatic measurement reduce electric shock accident for worker

K7GE helps reduce risk of work accidents such as electric shocks since measurement is automatic and does not require manual tasks.

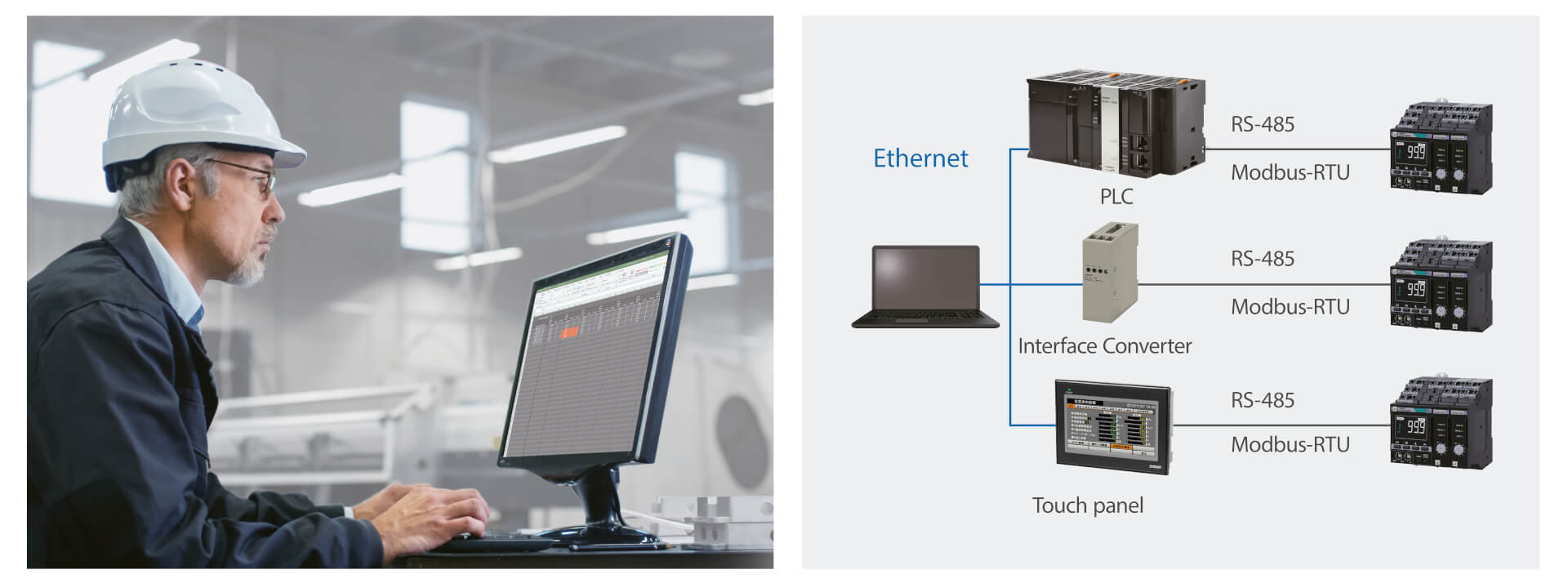

Remote condition monitoring for automatic insulation resistance measurement

K7GE enables remote monitoring from the office via network connection using a touch panel, PLC, and communications converter. It also allows on-site measurement results confirmation and parameter setting changes via the Main Unit indicator.

User-friendly features that support the trend monitoring

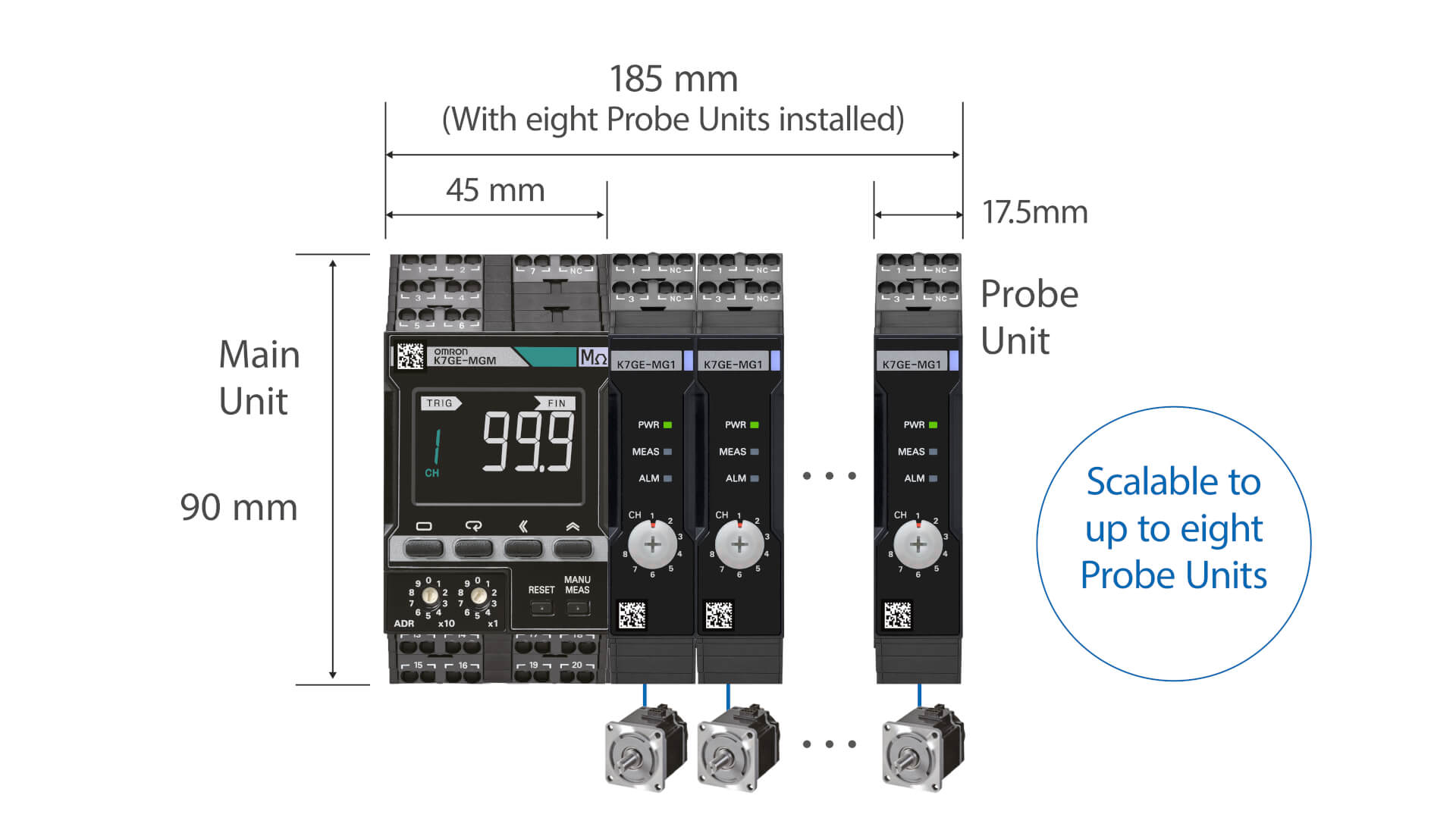

K7GE supports up to eight Probe Units for measurement targets on the same system. It provides for a space-efficient installation as the number of Probe Units can be scaled in accordance with the number of measurement targets.

*1. The Main Unit and Probe Units are sold separately; purchase in the required combination for use.

2. Easy to install and retrofit

Easy to retrofit since it can be used just by wiring to the power cable of the target equipment.

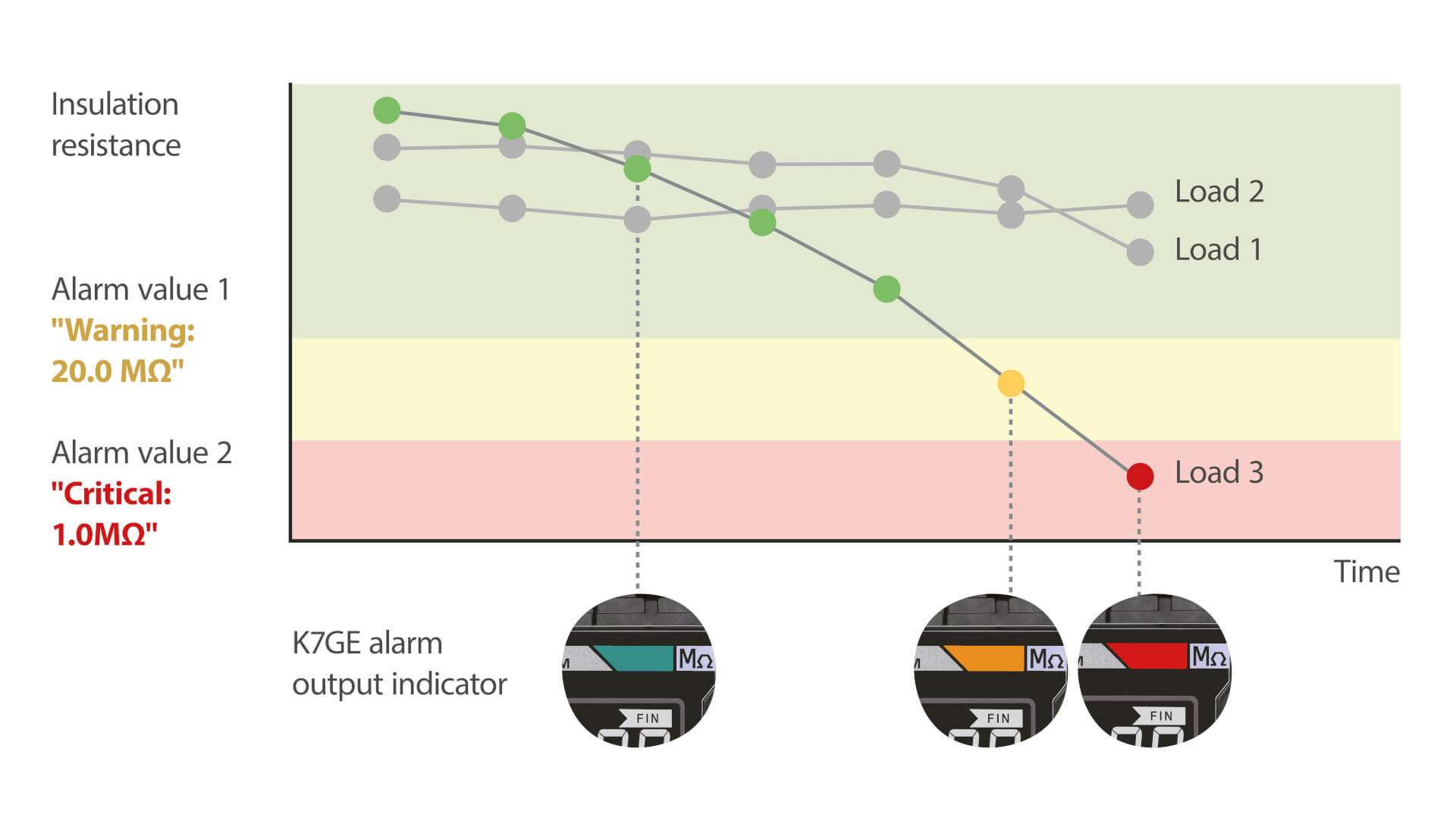

3. Maintenance timing notification by two-level alarm: warning and critical

The threshold for indicating the degree of degradation can be set in two levels. Anomaly scan also be confirmed through communications data. This feature enables identifying the optimal timing for maintenance without visiting the site frequently. Furthermore, a load (such as an anomaly detection indicator) can be directly connected to the units transistor alarm outputs.

*2. Factory default settings

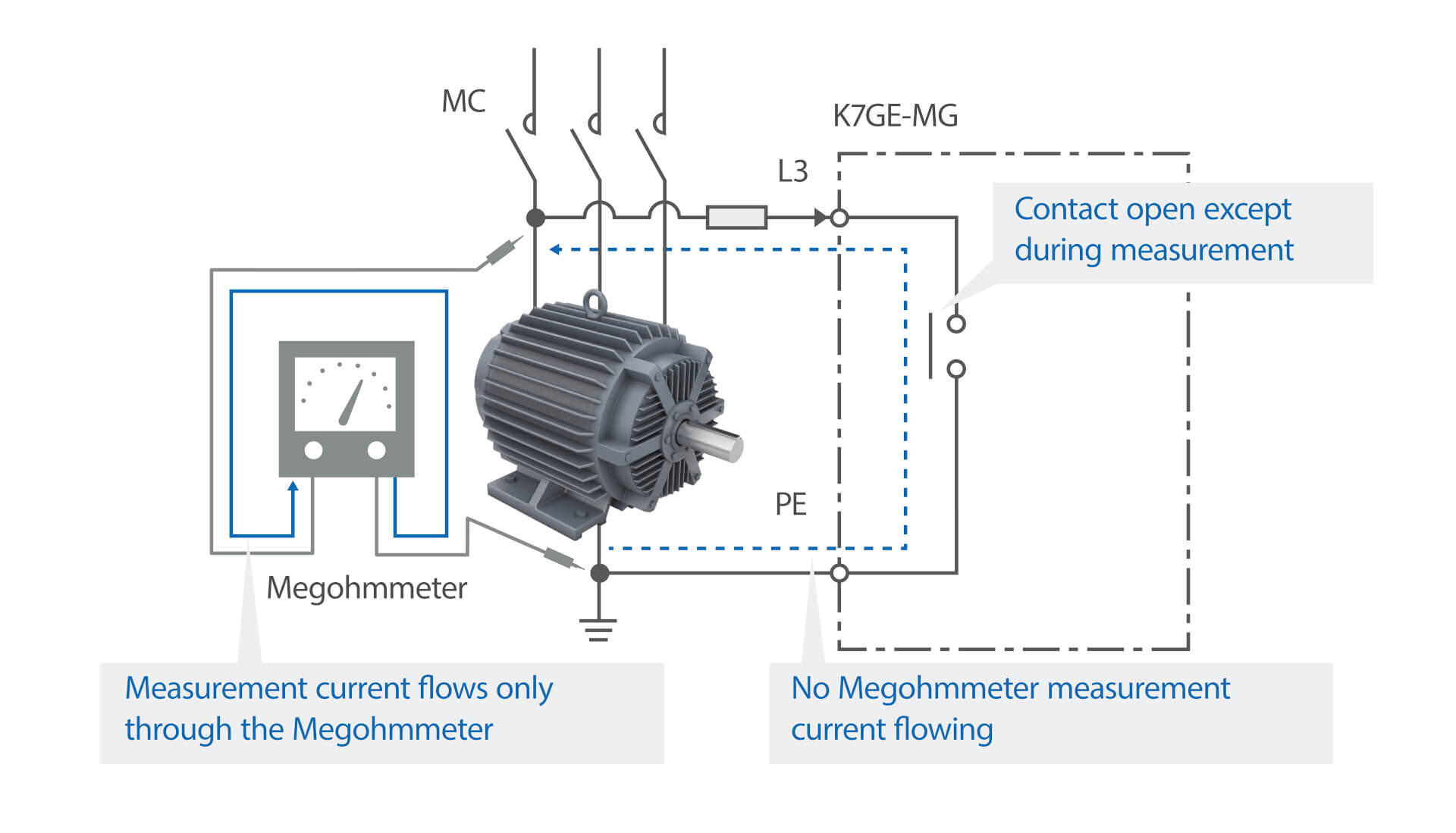

K7GE does not have any impact on measurement results by the Megohmmeter since its internal drycontact isolates it from the equipment target of measurement, except during measuring. Whenneeded, it can easily support measurement by calibrated measuring equipment as well.

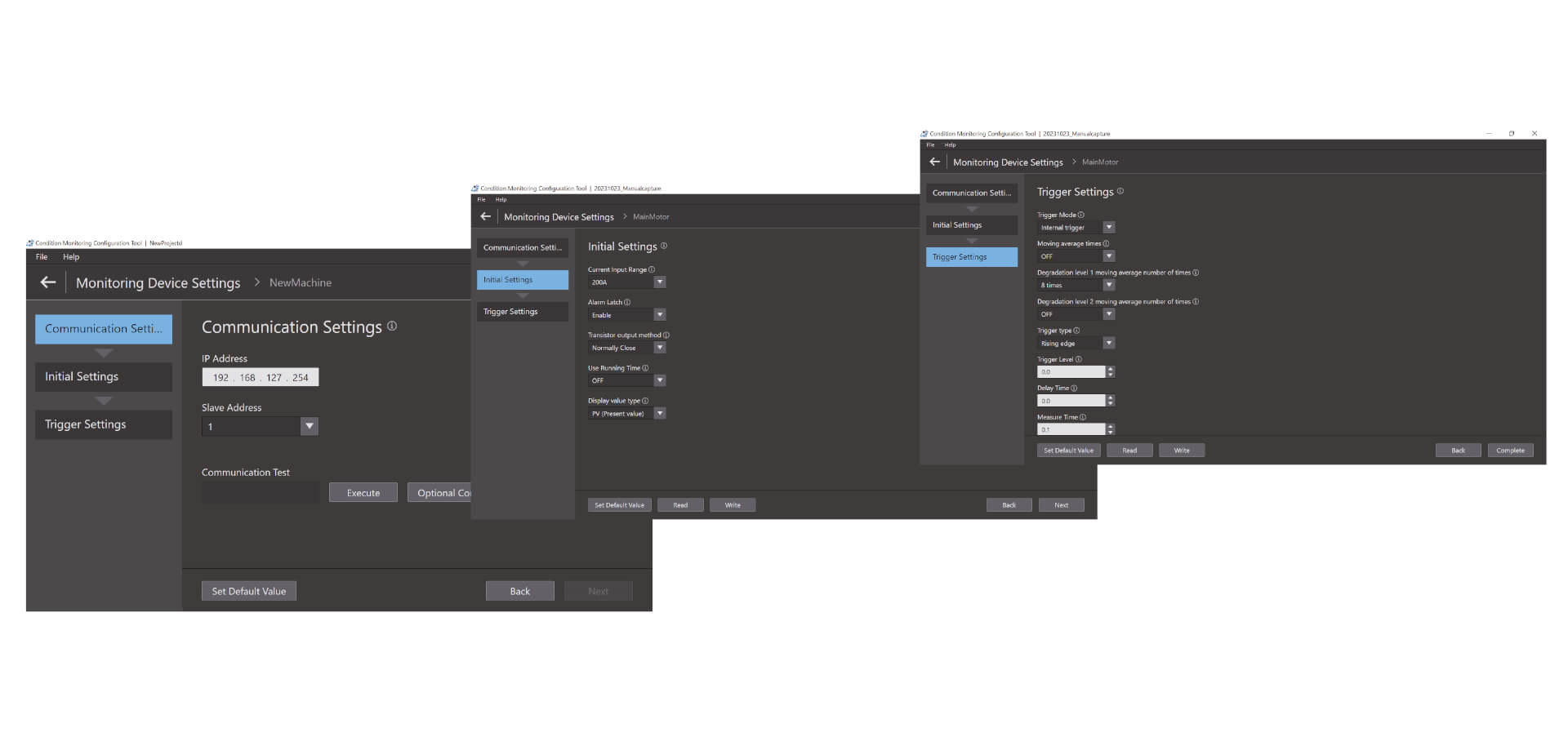

Condition monitoring devices can be configured with a single tool

Easy three-step configuration The Condition Monitoring Configuration Tool allows for batch configuration of a wide range of condition monitoring devices, such as those for monitoring motors, temperatures, insulation, and heaters. It can be used without any special skills, reducing training effort

Easy three-step configuration

The Condition Monitoring Configuration Tool allows for batch configuration of a wide range of condition monitoring devices, such as those for monitoring motors, temperatures, insulation, and heaters. It can be used without any special skills, reducing training effort. Setup can be completed in just three steps: communications setup, initial setup, and trigger setup.*1 With its high operability, the tool boosts on-site productivity as well.

Videos

-

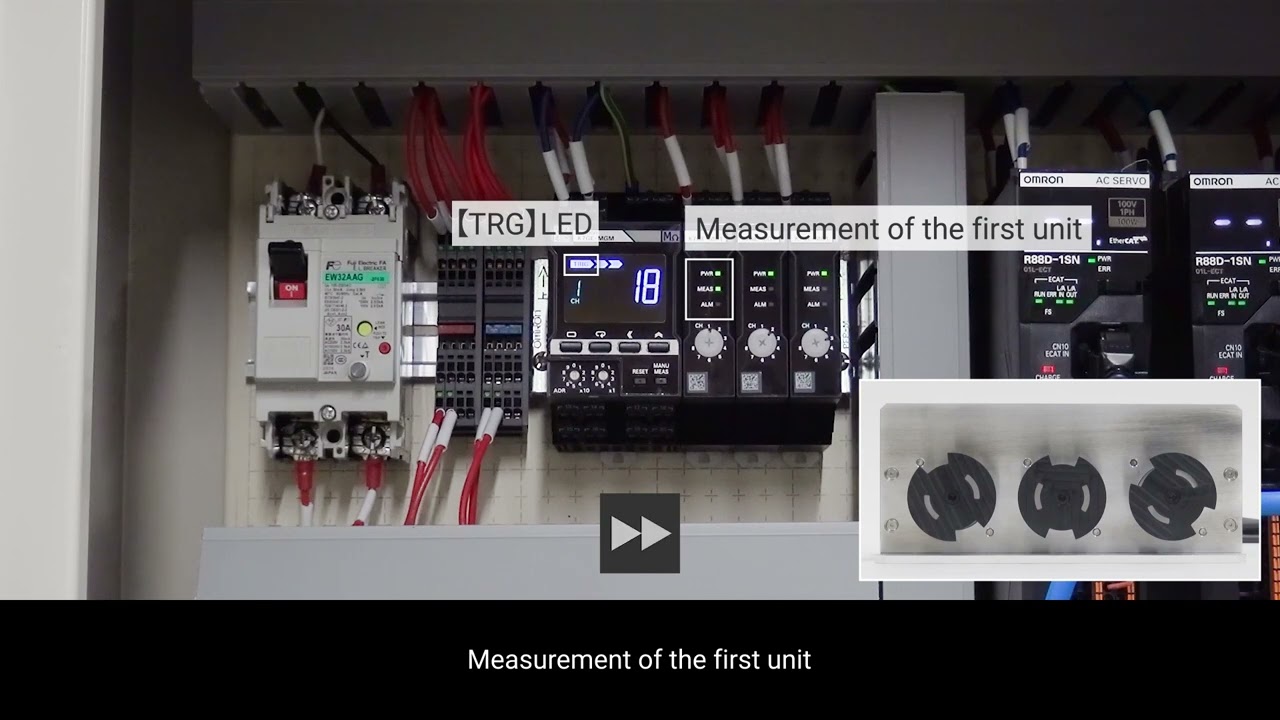

OMRON K7GE insulation resistance monitoring device: basic operation demonstration

This is a demonstration video about insulation resistance measurement using the OMRON K7GE-MG for 3 motors. For more information, visit:

02:10

OMRON K7GE insulation resistance monitoring device: basic operation demonstration

This is a demonstration video about insulation resistance measurement using the OMRON K7GE-MG for 3 motors. For more information, visit:

-

Comparison between insulation resistance tester mega tester and OMRON K7GE condition monitor

In this video, we highlight the benefits of the OMRON K7GE condition monitoring device over the traditional insulation resistance meter (mega ohm tester). For more information, visit:

01:48

Comparison between insulation resistance tester mega tester and OMRON K7GE condition monitor

In this video, we highlight the benefits of the OMRON K7GE condition monitoring device over the traditional insulation resistance meter (mega ohm tester). For more information, visit:

-

Installing the OMRON K7GE condition monitoring device when the load is an inverter-driven motor

In this video, you can see how to install the OMROn K7GE condition monitoring device when the load is an inverter-driven motor. For more information, visit:

03:20

Installing the OMRON K7GE condition monitoring device when the load is an inverter-driven motor

In this video, you can see how to install the OMROn K7GE condition monitoring device when the load is an inverter-driven motor. For more information, visit:

-

Installing the OMRON K7GE condition monitoring device when the load is a servo motor

In this video you can see how to install the OMRON K7GE condition monitoring device when the load is a servo motor. For more information, visit:

03:20

_instruction_sheet_en.jpg)