5 practical ways to build smarter, leaner, and more reliable control panels

Published on 05 August 2025 in Operational Excellence

1. Prioritise compact design to optimise space

Space inside machines and production lines is always limited. Using compact components allows for smaller control panels, which reduces material use and frees up space for other functions such as safety devices or additional automation. You can also improve airflow, which decreases the need for additional cooling and saves energy.

Smaller does not mean sacrificing performance. Uniform component sizes, slim relay systems, and efficient layouts reduce wasted space and make panels easier to assemble, expand, or maintain.

Example: OMRON’s Value Design for Panel components feature standardised dimensions, slim housings, and side-by-side mounting capability, helping reduce control panel size by up to 20 percent and simplifying the layout.

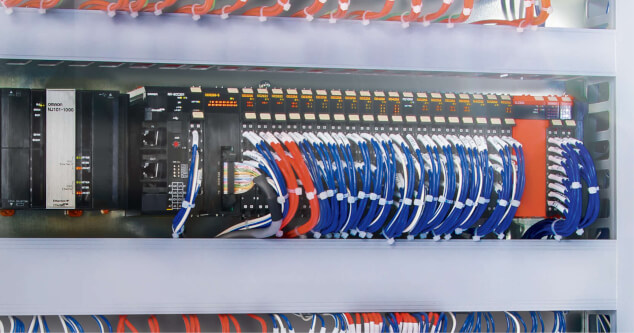

2. Simplify wiring to save time and improve reliability

Wiring is often the most time-consuming part of panel assembly. It can also be a common source of errors if not handled carefully. Simplifying the wiring process reduces build time and improves the long-term reliability of the panel.

Technologies like push-in terminals allow for tool-free, front-facing wiring that holds firmly in place, even in environments exposed to vibration or mechanical stress.

Example: OMRON’s Push-In Plus terminals allow fast, tool-free wiring while providing a secure connection. The terminals hold the wires firmly in place, eliminating the need for retightening and reducing the risk of connection failures during operation or transport.

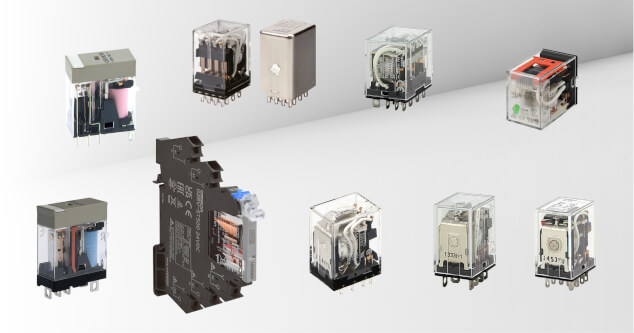

3. Build for long-term system reliability

Control panels need to operate dependably under various conditions, from high-vibration environments to temperature extremes. The reliability of components inside the panel directly impacts overall machine uptime and reduces unexpected maintenance.

Selecting globally certified high-quality relays, monitoring devices, and power supplies improves system durability and minimises the risk of faults that can disrupt production or damage equipment.

4. Monitor critical parameters to protect equipment

Unexpected voltage fluctuations, phase loss, or current irregularities can damage sensitive equipment and disrupt production. Integrating monitoring relays within your control panels provides early warnings of electrical issues. This helps protect machinery and maintain consistent quality.

Monitoring devices also help operators comply with regulations, avoid costly downtime, and extend the lifespan of production assets.

Example: OMRON’s K8DT monitoring relays safeguard against voltage asymmetry, phase loss, and current irregularities, providing real-time alerts to prevent failures in industries ranging from food production to semiconductor manufacturing.

5. Choose power supplies that enhance system stability

Reliable, space-efficient power supplies are essential for panel performance, especially when operating in harsh environments or limited spaces. Compact, vibration-resistant power supplies reduce the risk of unexpected downtime, simplify wiring, and optimise control panel layouts, while providing stable power to all connected devices.

Example: The OMRON S8VK series offers a complete range of compact, reliable power supplies, including models with Push-In Plus technology for easy installation. Their robust design ensures reliable operation, even in demanding conditions such as high temperatures.

Conclusion: Smarter panels deliver more than just space savings

Building efficient, reliable, and space-saving control panels improves machine performance, reduces maintenance effort, and contributes to more flexible production environments.

By applying these principles, and leveraging proven technologies such as OMRON’s Value Design for Panel components, monitoring relays, and compact power supplies, manufacturers can simplify panel construction, increase reliability, and maximise the limited space available in control cabinets and machinery.

Read more about OMRON’s Innovations in Panel Building

Contact us for more information