E5_C

High performance & simplicity

The next generation E5_C temperature controller is setting a new global standard in terms of precision and user-friendly design. Best control performance, easy set-up and outstanding visibility of the white IP66 LCD display have been integrated into a spacesaving housing only 60 mm deep.

- Fast and precise regulation: 50 ms sampling loop period time

- Easy to set up, and operate intuitively via CX-Thermo without power supply

- Best contrast display using white LCD technology which is visible from a far distance and from any angle

- Useful alarm and diagnosis functions for secure operation

- Practical timer and logic operation functions eliminating the need of a PLC

- Additional models with different features are available. Please check related product catalogue.

Specifications & ordering info

| Product | Size | Functions | Number of control loops | Temperature input type | Linear analog input type | Temperature range | Features | Number of event inputs | Number of alarm outputs | Supply voltage AC | Supply voltage DC | Control output | Communication port(s) | Terminal type | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

1/4 DIN (96 x 96 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 4 | 100-240 V | Linear current | Screw | Temp. controller, PRO; 1/4 DIN (96x96 mm); t/c & Pt100 & analog;4 alarms; 1st out current (lin) |

|

|||

|

|

1/4 DIN (96 x 96 mm) | ON/OFF control, PID control, Positional proportional control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | 2 Relay | Serial RS-485 | Screw | Temp. controller, PRO,1/4 DIN (96x96mm),1 x Valve OUT + Pot.,4 AUX,EVT. I/P 4,RS-485,Transf. OUT,100-240 VAC |

|

|

|

|

1/4 DIN (96 x 96 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 4 | 100-240 V | Voltage pulse | Screw | Temp. controller, PRO; 1/4 DIN (96x96 mm); t/c & Pt100 & analog;4 alarms;1st out 12 VDC |

|

|||

|

|

1/4 DIN (96 x 96 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 4 | 100-240 V | 2 Relay | Screw | Temperature controller, PRO; 1/4 DIN (96 x 96 mm); t/c & Pt100 & analog;4 alarms;1st out relay; 2nd out relay |

|

|||

|

|

1/4 DIN (96 x 96 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 4 | 100-240 V | Relay | Screw | Temp. controller, PRO; 1/4 DIN (96x96 mm); t/c & Pt100 & analog;4 alarms;1st out relay |

|

|||

|

|

1/4 DIN (96 x 96 mm) | HB/HS alarm for 1-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 4 | 4 | 100-240 V | Relay | Screw | Temp. controller, PRO; 1/4 DIN (96x96 mm); t/c & Pt100 & analog;4 alarms;1st out relay;Event IP ( 4);HBA;SSR failure |

|

|||

|

|

1/4 DIN (96 x 96 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 4 | 20.4-26.4 V | 20.4-26.4 V | Relay | Screw | Temp. controller, PRO; 1/4 DIN (96x96 mm); t/c & Pt100 & analog;4 alarms;1st out relay |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 3 | 100-240 V | Linear current | Screw | Temperature controller, 1/16 DIN (48x48 mm), 0/4-20 mA current output, 3 AUX, 100-240 VAC |

|

|||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 3 | 100-240 V | Linear current | Serial RS-485 | Screw | Temperature controller, 1/16 DIN (48x48 mm), 0/4-20 mA current output, 3 AUX, 2 Event input, RS-485, 100-240 VAC |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Transfer output | 2 | 3 | 100-240 V | Linear current | Screw | Temperature controller, 1/16 DIN (48x48 mm), 0/4-20 mA current output, 3 AUX, 2 Event input, Transfer output, 100-240 VAC |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 3 | 20.4-26.4 V | 20.4-26.4 V | Linear current | Screw | Temperature controller, 1/16 DIN (48x48 mm), 0/4-20 mA current output, 3 AUX, 24 VAC/DC |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 3 | 20.4-26.4 V | 20.4-26.4 V | Linear current | Serial RS-485 | Screw | Temperature controller, 1/16 DIN (48x48 mm), 0/4-20 mA current output, 3 AUX, 2 Event input, RS-485, 24 VAC/DC |

|

|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 4 | 3 | 20.4-26.4 V | 20.4-26.4 V | Linear current | Screw | Temperature controller, 1/16 DIN (48x48 mm), 0/4-20 mA current output, 3 AUX, 4 Event input, 24 VAC/DC |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Transfer output | 2 | 3 | 20.4-26.4 V | 20.4-26.4 V | Linear current | Screw | Temperature controller, 1/16 DIN (48x48 mm), 0/4-20 mA current output, 3 AUX, 2 Event input, Transfer output, 24 VAC/DC |

|

|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP | 2 | 3 | 20.4-26.4 V | 20.4-26.4 V | Linear current | Screw | Temperature controller, 1/16 DIN (48x48 mm), 0/4-20 mA current output, 3 AUX, 2 Event input, Remote Setpoint, 24 VAC/DC |

|

|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 3 | 100-240 V | Voltage pulse | Screw | Temperature controller, 1/16 DIN (48x48 mm), 2 x 12 VDC pulse output, 3 AUX, 100-240 VAC |

|

|||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 3 | 20.4-26.4 V | 20.4-26.4 V | Voltage pulse | Screw | Temperature controller, 1/16 DIN (48x48 mm), 2 x 12 VDC pulse output, 3 AUX, 24 VAC/DC |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 100-240 V | Voltage pulse | Push-in | Temperature controller, 1/16DIN (48 x 48mm), 12 VDC pulse output, 2 x auxiliary relay outputs, universal input type, 100-240 VAC |

|

|||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 100-240 V | Voltage pulse | Screw | Temperature controller, 1/16 DIN (48x48 mm), 12 VDC pulse output, 2 AUX, No cover, 100-240 VAC |

|

|||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 100-240 V | Voltage pulse | Plug-in | Temp. controller, PRO, 1/16 DIN (48 x 48 mm), Plugin-type, 2 AUX, 1 x 12 VDC pulse OUT, 100 to 240 VAC |

|

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact me E5_C

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for E5_C

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadFeatures

LCD display

Easy Set-up

Precise control

Useful functions

Parameter Masking

-

Omron E5_C series Temperature Controller – Parameter Mask Function

With Omron’s Parameter Mask Function with CX-Thermo Software, you can easily prevent mistakes It might be necessary to protect your machine or device against unwanted manipulation, which can provoke hazardous risks to the health of operators or could cause several after-sale troubles caused by wrong parameters setting A very effective way to e.g. limit the access for certain settings would be either to a blank (mask) them, not allowing the access for unauthorized operators, or to protect the temperature controller by password setting (stronger). The Parameter Masking means that Parameters are hidden but present in the background but not accessible and can only be changed by legitimated users with defined access rights.

04:04

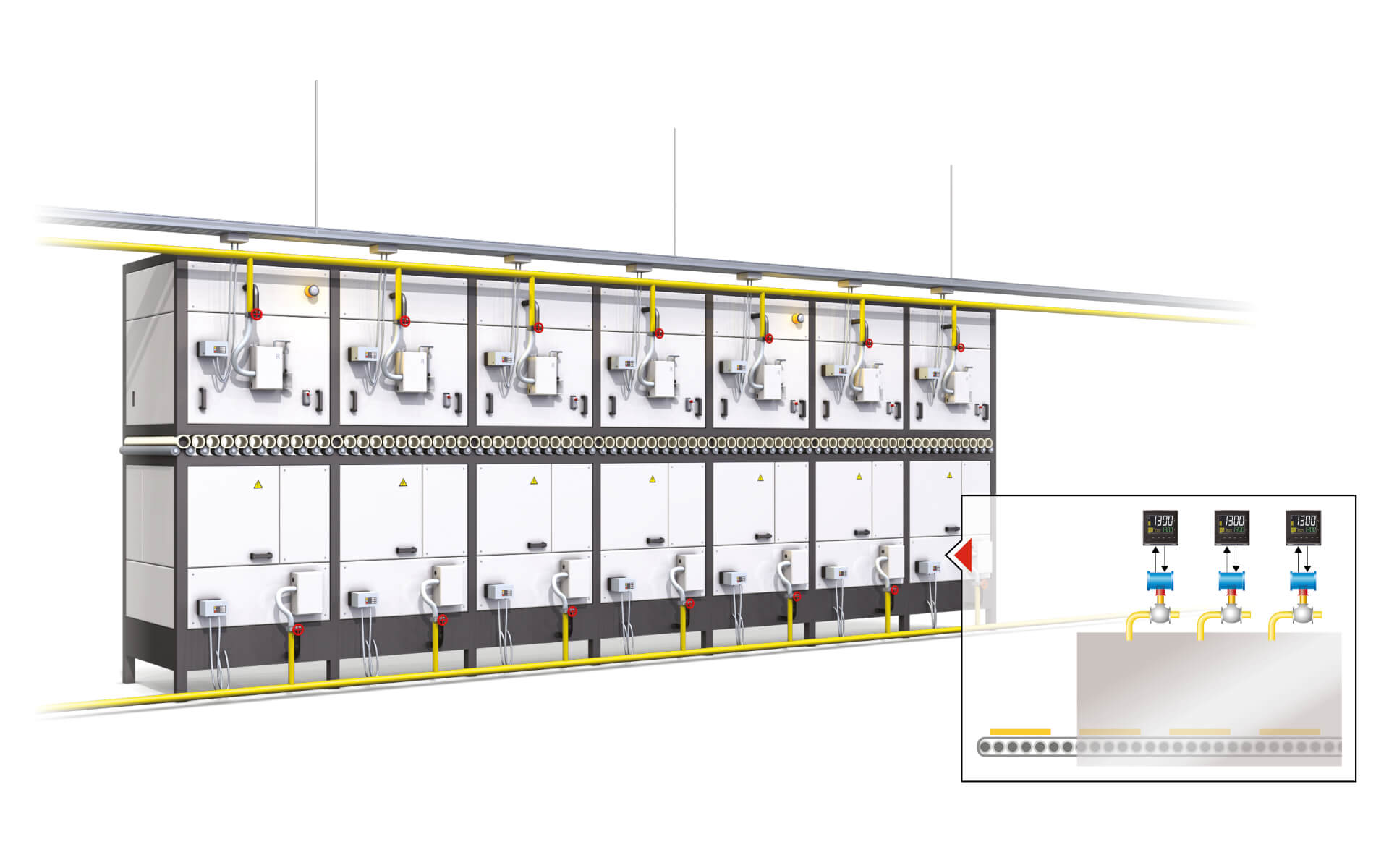

Reduce Crossover Wiring with Horizontal Connection Structure

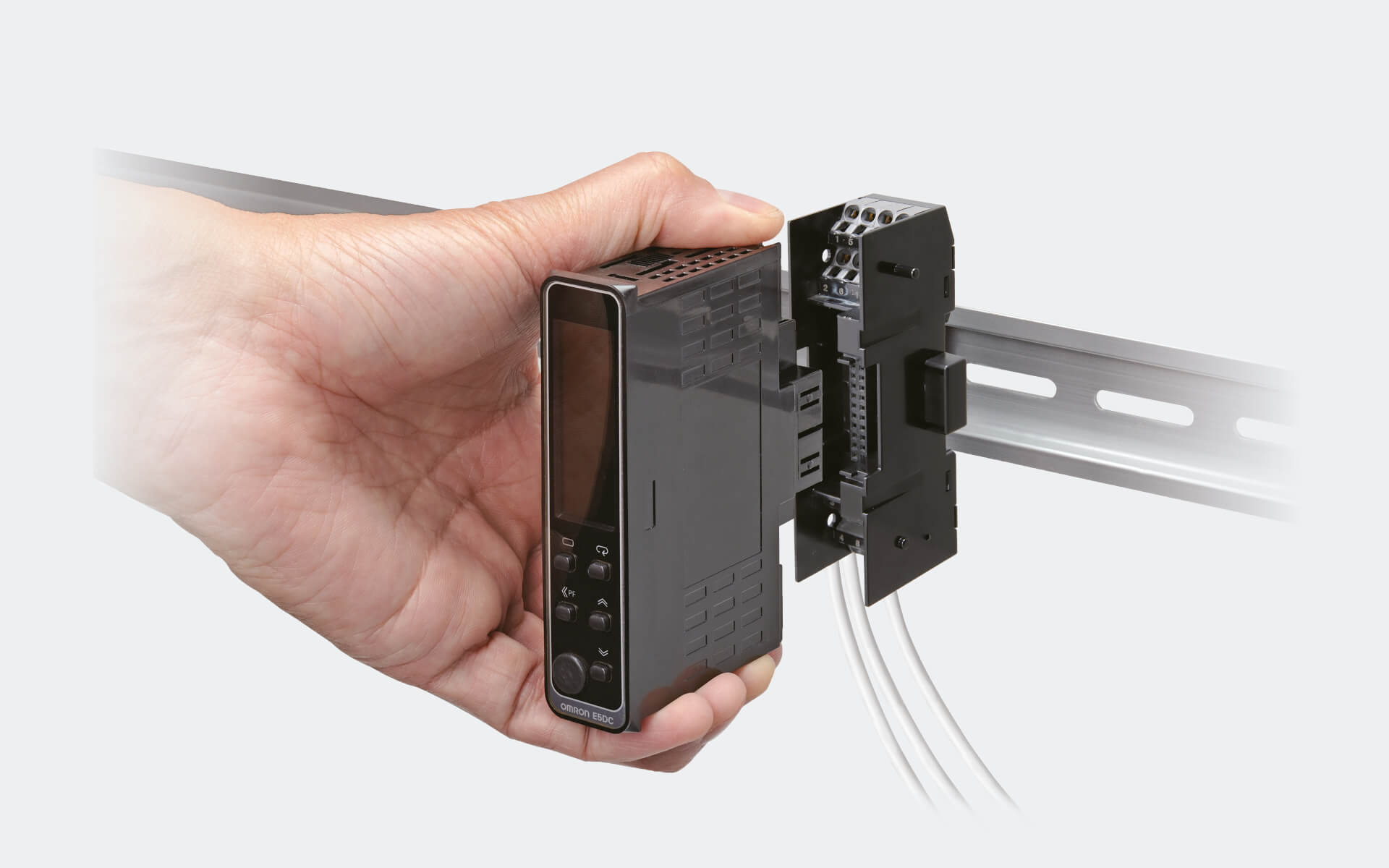

Removable socket for easy maintenance

Applications

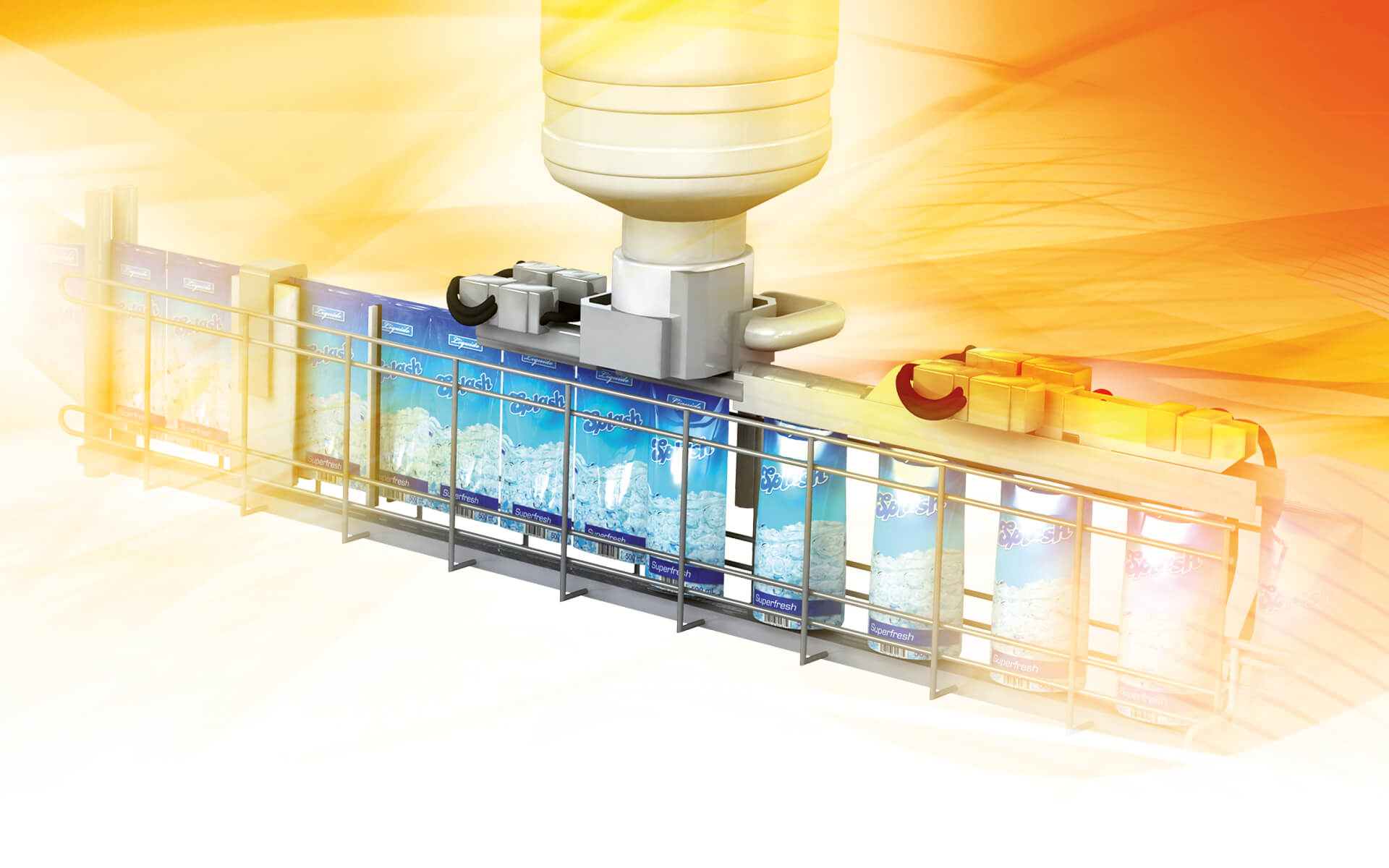

Bag sealing

In sealing applications speed of recovery is very important. Each time the sealing jaws close heat is drawn away into the product. The ability of the E5_C to read and react to any drop in temperature means that the quality of the seal is maintained while operating at high or low speeds. In case of alarm or malfunction the bright blinking display is warning the operator instantly so he can carry out counter measures

Harsh environment

Control products can be subjected to harsh environments where they can be splashed during the process or covered in dust or get warm through their location. The E5CN, E5CSV, H7CX, H5CX and K3HB all feature a NEMA4X (IP66 equivalent) front panels so are suitable for the use in these applications, also the low profile fascia means that they are less prominent in the front of the panel and so less likely to become dirty.

Oven control

External influences can cause the temperature to deviate from the required set value. With the E5CC it is possible to program the level at which the display starts blinking. Alarm options include deviation from set point, where if the set point is changing the alarm moves with it. Absolute alarms where they are referenced to 0, standby so the alarms will not be active during the set point has been reached. Latching which means that once triggered they can only be deactivated by removing power. This is ideal for remote or unmanned processes, as the alarm will remain until the machinery is next visited.

Baking oven

In many applications it is important to control the speed of approach to set point as well as maintain it at a preset time once reached. This rate of rise control helps to prevent over cooking of the outside of the product. However multistage control is not normally required. The E5CC contains a simple two stage function, controlling the rise to set point and also the sinking of temperature versus time can be programmed.

Expertise

Applications

Faster input sampling and control period

This gives faster, more precise heater control in rapidly changing, disturbance-sensitive applications. With a sampling period time of only 50ms any quick changing processes can be reliably regulated.

Process Value blinking display

This provides crystal-clear process status, even from a distance and without the need for interpreting the values. When one of the heaters is not at set-point the Process Value can start blinking to alert any member of staff (detecting a bad sealing at an early stage, for example).

Loop break alarm and sensor break alarm (with forced MV option)

In plastics production the tool used to make the product is changed quite often. Frequent reconnecting of the sensor or heater can result in a wire break (a broken thermocouple, for example). These alarms quickly detect such problems in the process.

Basic (2-step) programmer

In many thermal processes (food, brick, pottery etc.) a small element of timing is required. This feature enables you to ramp up to a set-point and set the dwell time period. At the end of this time, the process stops or continues with an indication alarm to alert the operator. With this feature, a fixed minimum or maximum curing/baking time is assured in a smooth, controlled way. Alternatively you can set different steepness for the ramp-down period, e.g. allowing a soft decrease of temperature to avoid structural cracks of the heat treated object.

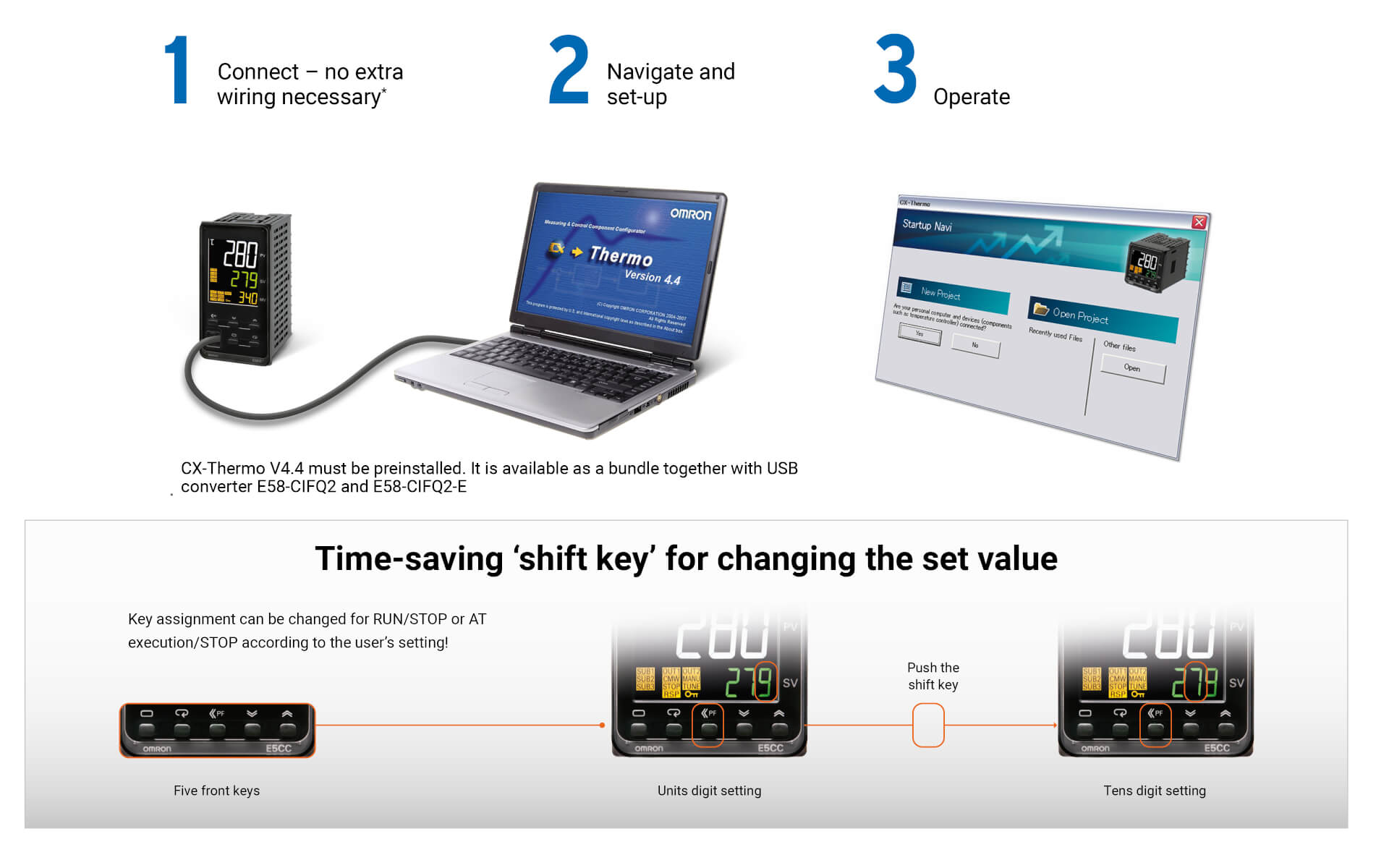

Easy to connect, set-up and operate

The E5_C series can be easily connected, set-up and operated in only a few steps using the instrument’s 5 front keys. Our CX-Thermo software and useful navigation assistant for intuitive settings is allowing a very quick parameter setting, easier device adjustment and simpler maintenance.

Software

ThermoMini

ThermoMini is a simple to use PC based support tool to manage parameters for our Temperature Controllers. All parameters are handled in one block and can be uploaded from one E5_C and downloaded into another one, but can also be stored on and retrieved from PC hard-disk as CSV file. The CSV file is easy to read and can be printed for filing or checking. You can change one parameter at the time on the controller which is on-line (one at the time). ThermoMini is tested on W98-SE, Windows2000 and Windows XP

We however recommend to use CX-Thermo for more functionality to program, clone and optimize our Temperature Controllers.

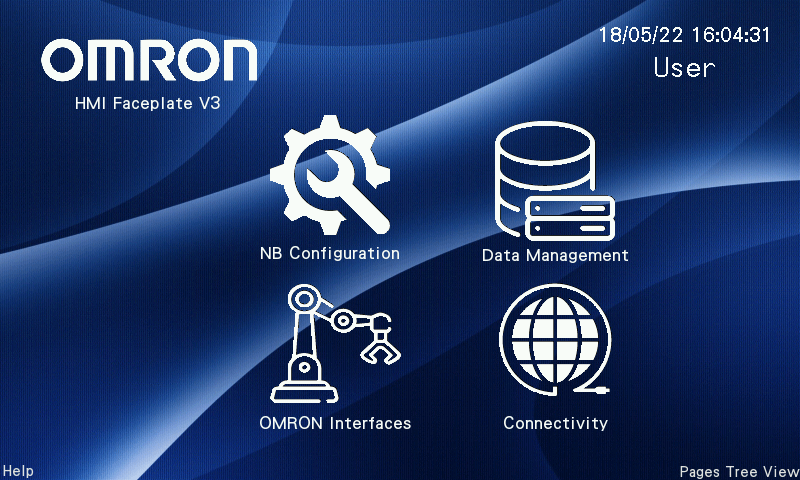

Faceplates for HMI

- Getting started Project for E5_C series reducing development time to start working with Omron NB series HMI.

- Set & monitor main temperature controller functionalities: Control mode, Autotuning, alarm and much more.

- Connection via RS485 and Modbus/RTU protocol.

Download NB HMI faceplate project to reduce development time for HMI applications

Videos

-

The art of panel building (1): easy wiring

Watch the video in which Hank and René, our two electrical control panel specialists, introduce a new patented Push-In Plus technology. You may also fast forward to the parts that really interest you: 1:06 - Easy to insert (easier than an earphone jack!) and secure connection 2:05 - Work with both hands while the Push-In Plus terminal mechanism holds the screwdriver for you (This is really handy! Check it also at 4:17) 3:26 - Front-in and front release wiring 3:49 - The new terminal blocks with Push-In Plus technology 5:31 - Flexible mounting of sockets

07:36

The art of panel building (1): easy wiring

Watch the video in which Hank and René, our two electrical control panel specialists, introduce a new patented Push-In Plus technology. You may also fast forward to the parts that really interest you: 1:06 - Easy to insert (easier than an earphone jack!) and secure connection 2:05 - Work with both hands while the Push-In Plus terminal mechanism holds the screwdriver for you (This is really handy! Check it also at 4:17) 3:26 - Front-in and front release wiring 3:49 - The new terminal blocks with Push-In Plus technology 5:31 - Flexible mounting of sockets

-

The art of panelbuilding (2): heat dissipation

Watch the 2nd in a series of three videos where Hank and René, our electrical control panel specialists, take a closer look at heat dissipation in your cabinet; how to identify thermal hotspots, which products to use and where to place them in your cabinet. You may also fast forward to the parts that really interest you: 00:23 Temperature control and heat dissipation in a control cabinet 01:40 Identifying thermal hotspots 03:14 Standard height for unobstructed air flow 03:39 Compact design 03:53 Less Heat dissipation 04:08 Power Management System

04:51

The art of panelbuilding (2): heat dissipation

Watch the 2nd in a series of three videos where Hank and René, our electrical control panel specialists, take a closer look at heat dissipation in your cabinet; how to identify thermal hotspots, which products to use and where to place them in your cabinet. You may also fast forward to the parts that really interest you: 00:23 Temperature control and heat dissipation in a control cabinet 01:40 Identifying thermal hotspots 03:14 Standard height for unobstructed air flow 03:39 Compact design 03:53 Less Heat dissipation 04:08 Power Management System

-

New Value for Electrical Control Panels

If you have to downsize your machine, export your machine overseas or have to cope with short lead times and labor shortage, this video might have some answers for you.

03:12

New Value for Electrical Control Panels

If you have to downsize your machine, export your machine overseas or have to cope with short lead times and labor shortage, this video might have some answers for you.

-

Fonmar- temperature controller makes bespoke requirement standard

The bespoke temperature control needs of one customer have been incorperated into our latest temperature control offering – the E5GC

03:30

_cg_en.jpg)